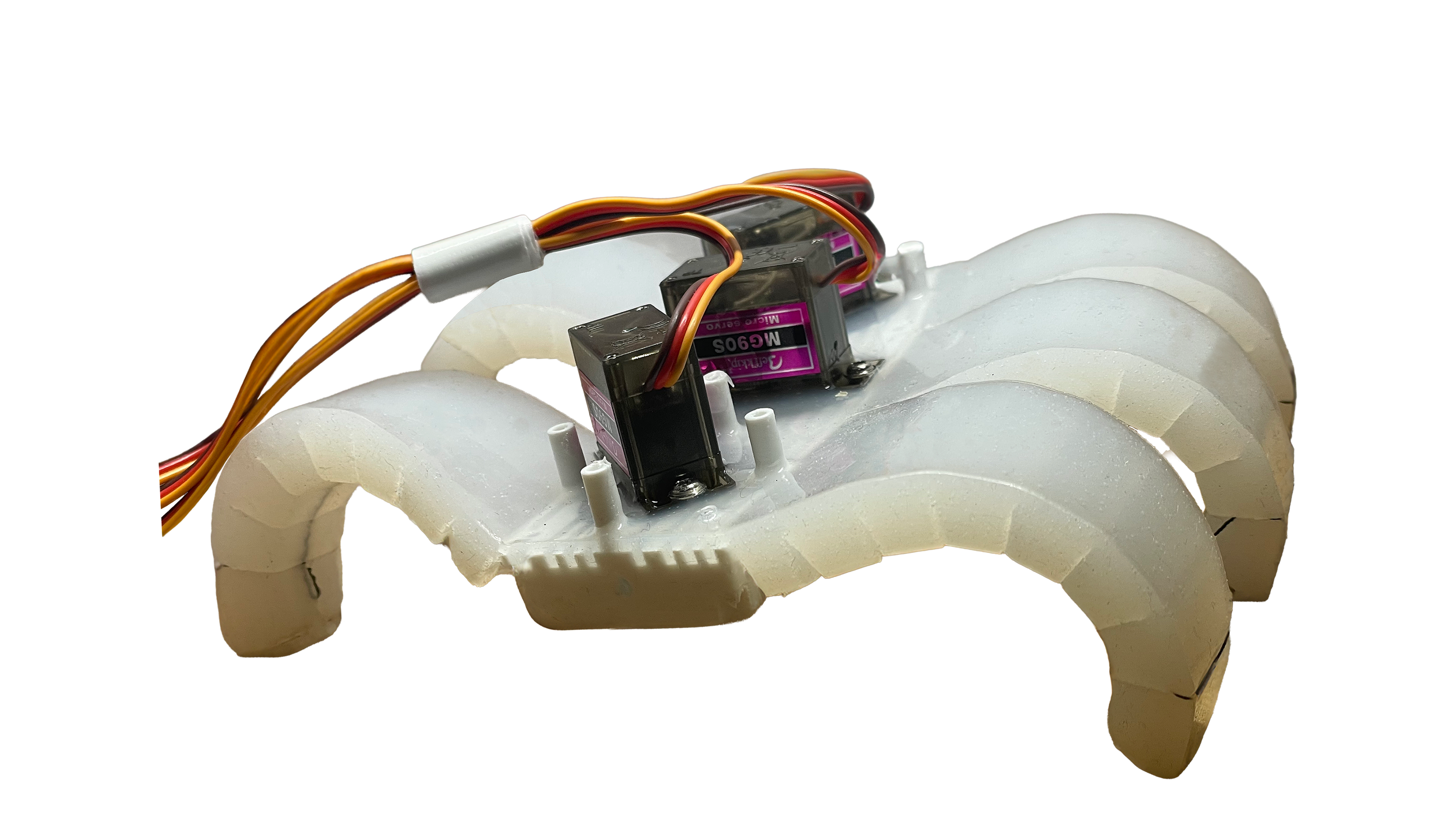

Exploded drawing view of assembly, featuring PLA enclosure and vertebrae, TPU shaft, 4 MG90s servos, Arduino board, and MPU-9250 6-axis gyroscope for sensing and positioning of end-effector.

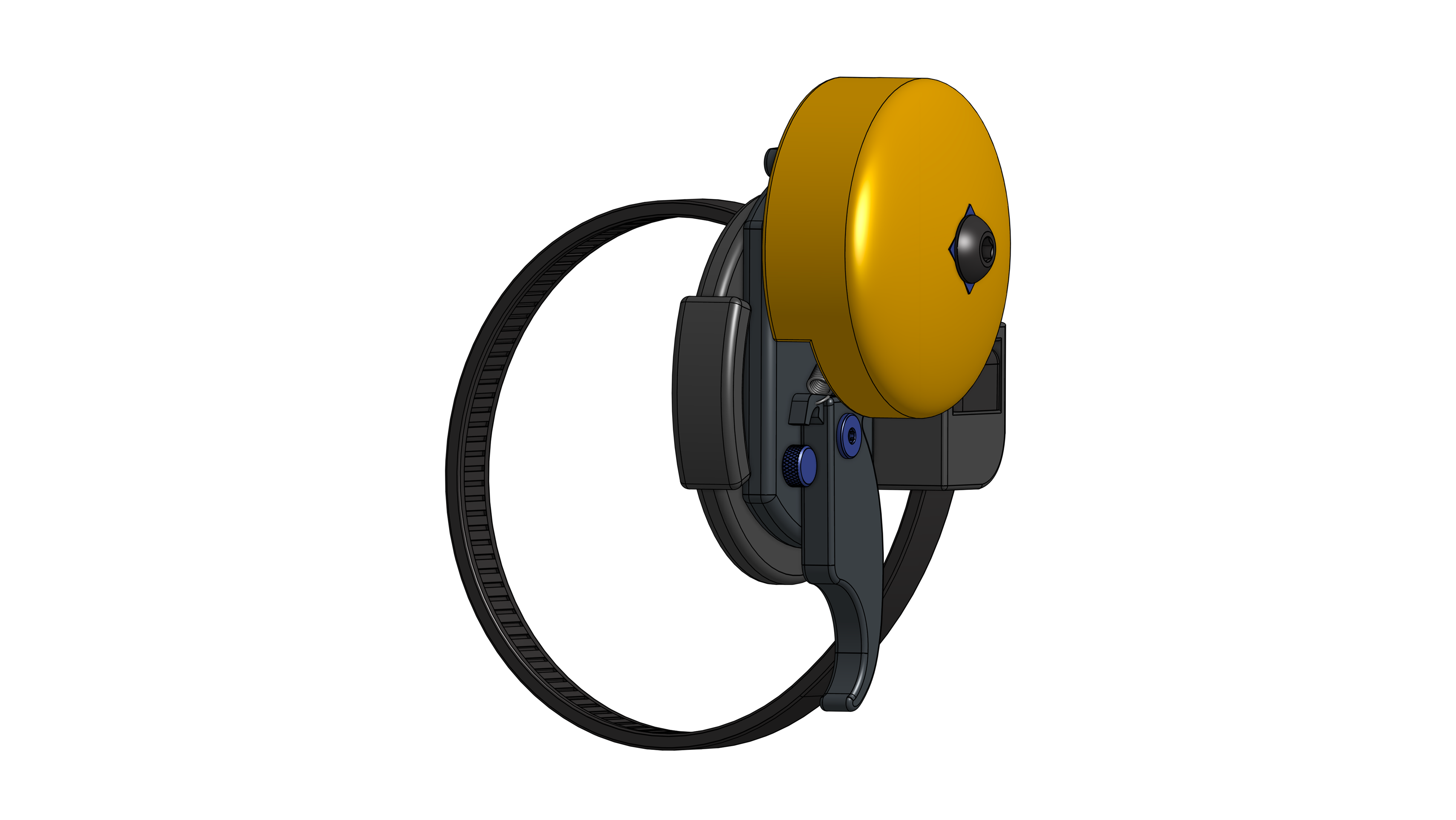

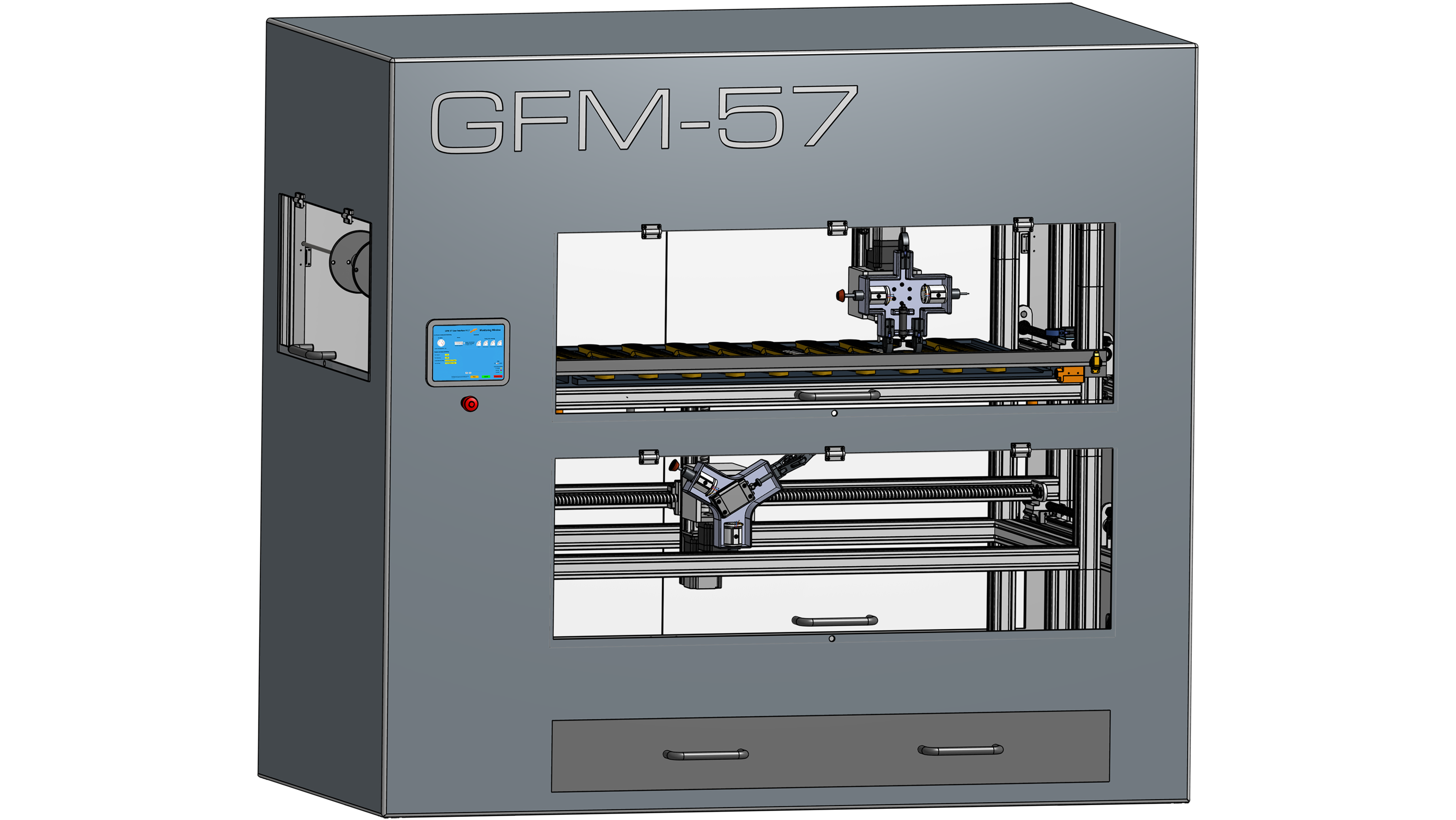

CAD rendering showing mounting of control board, cable routing channels, and power/data ports.

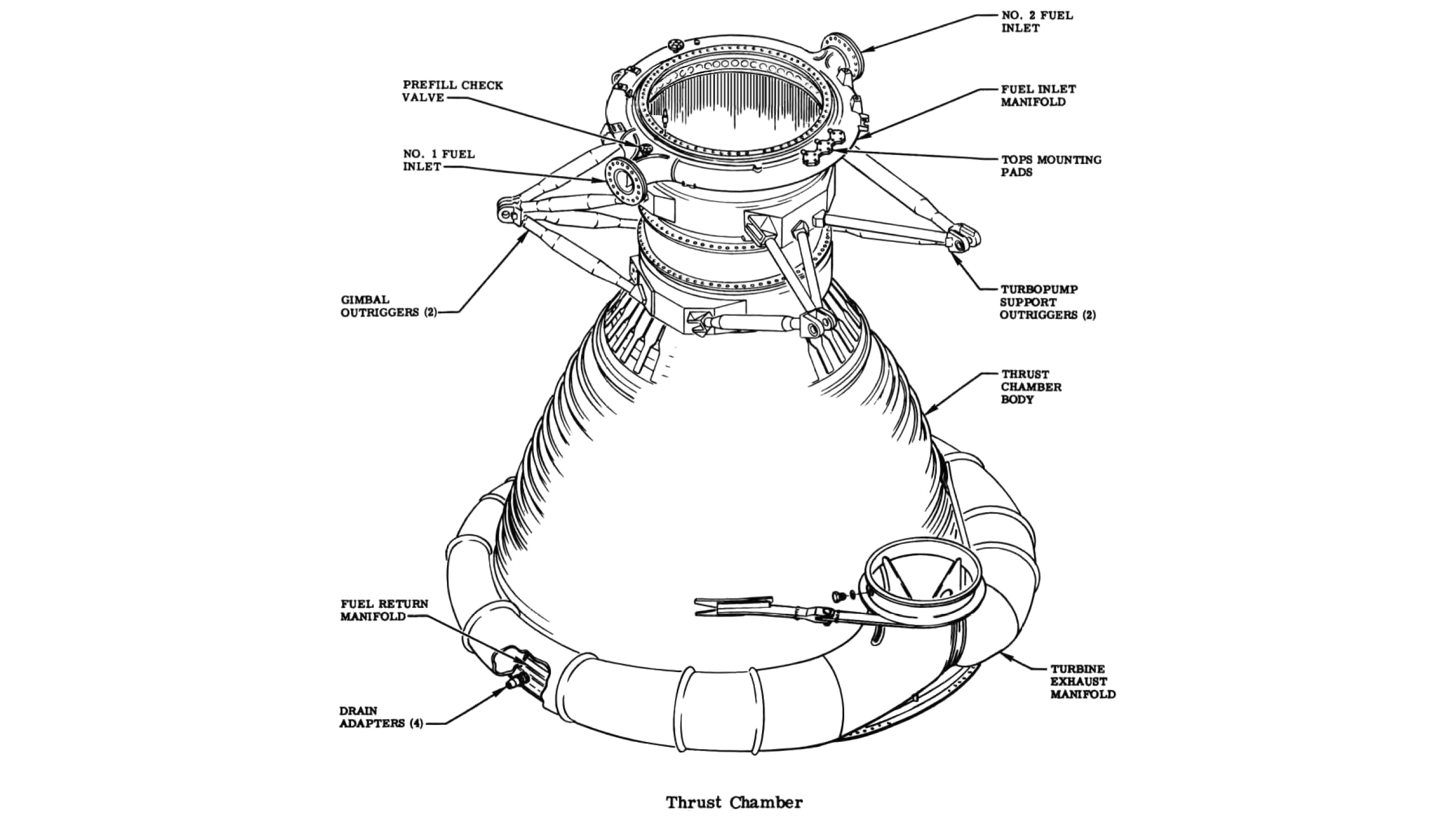

Labeled diagram with callouts to main components and features. The materials for all 3D-printed components are also specified.

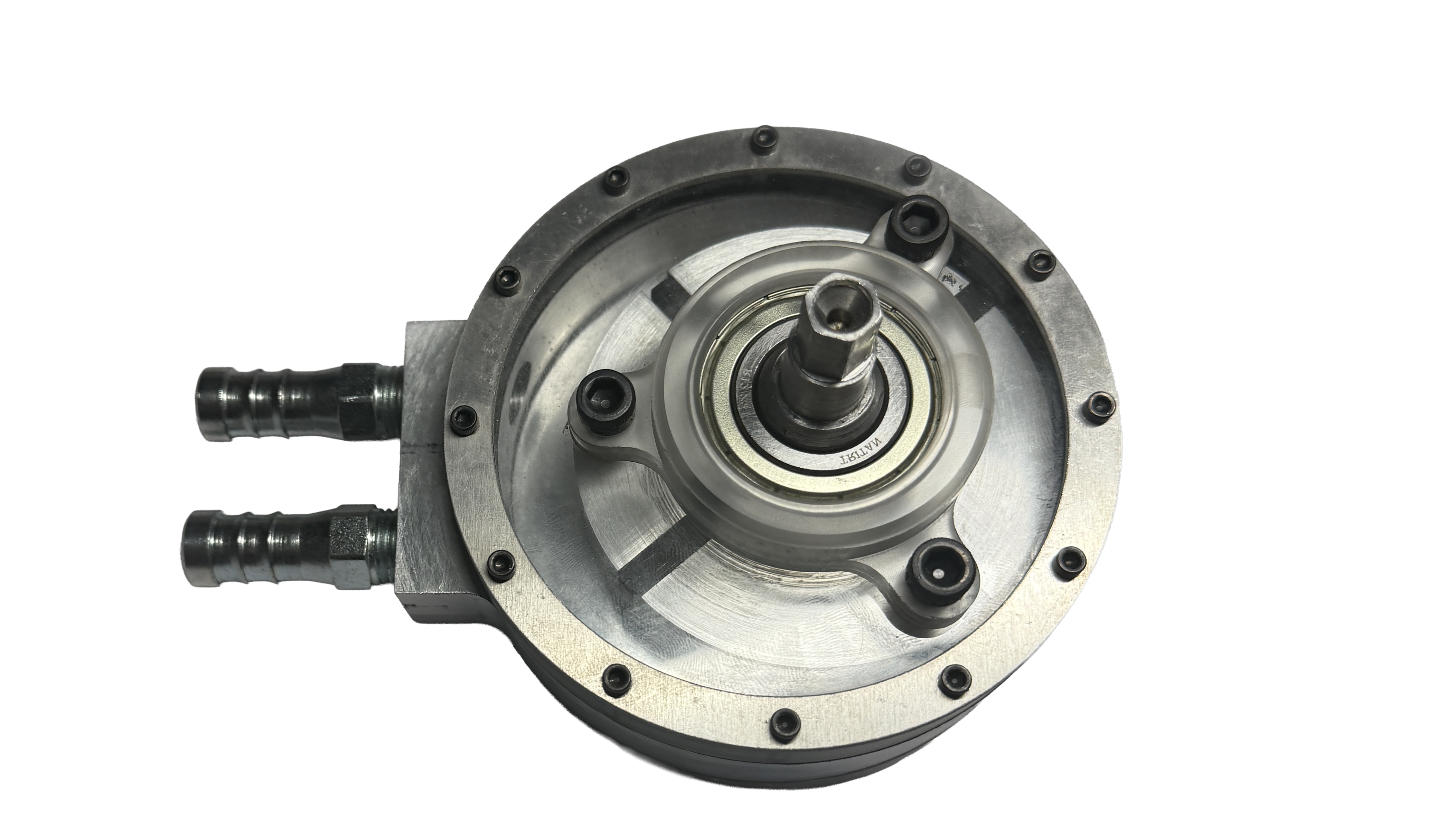

Functional device prototype.

Time-lapse video of 3D printing PLA components.

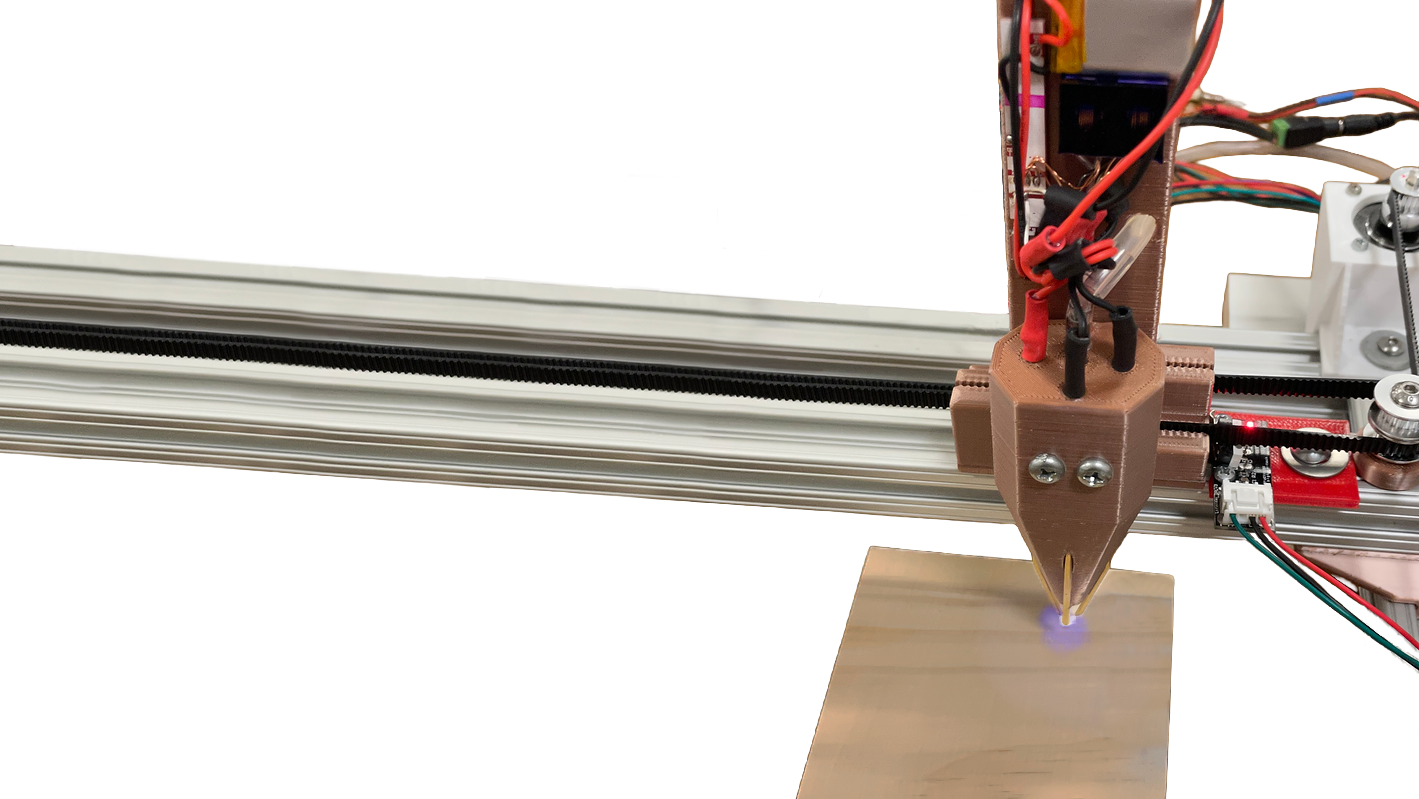

Initial assembly of electromechanical system on bench.

Video of completed platform in operation, showing active positional feedback on the serial monitor from the MPU-9250 gyroscope, and joystick control system.