Background

Problem Statement

Soft robots are defined by their use of highly-compliant materials, this makes them well-suited to navigating complex environments and performing delicate tasks.

However, it is very challenging to produce the necessary force transfers required for motion in soft robotic limbs and actuators, compared to conventional, "rigid" robots. These challenges must be addressed in order to fully leverage the advantages of soft robotic platforms.

Design

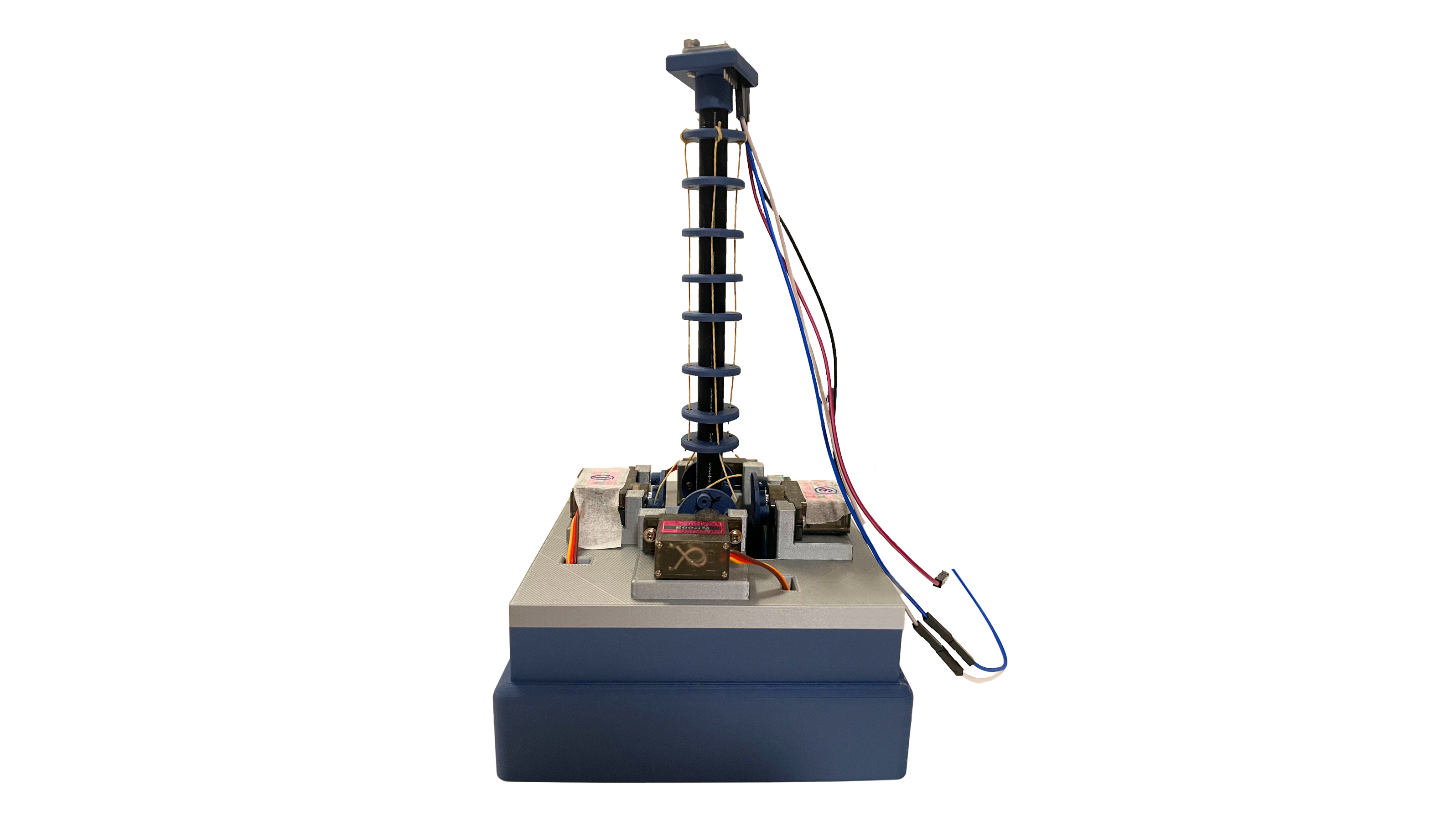

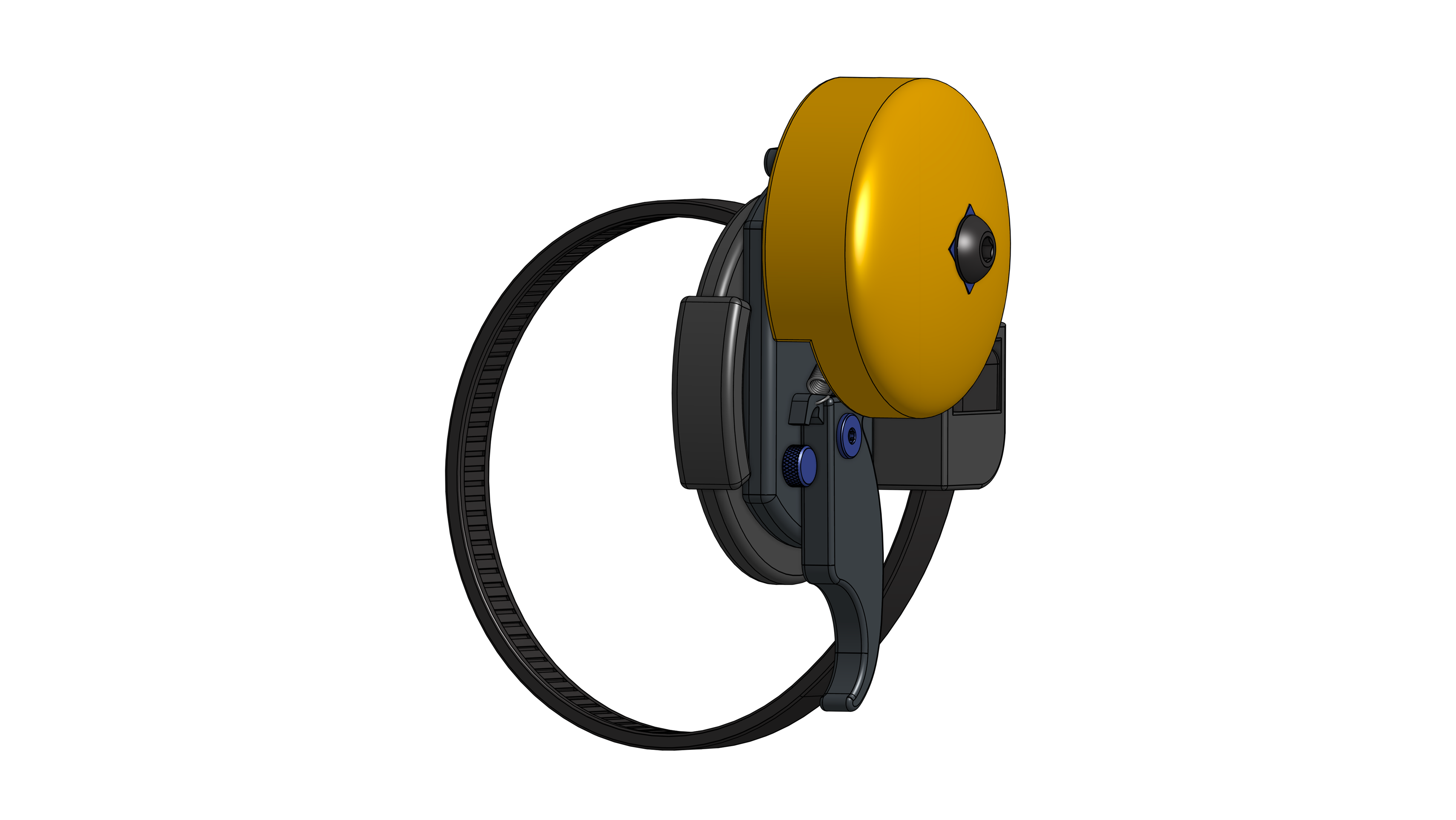

Exploded drawing view of final Starfish design. Featuring 3 MG90s metal-geared servos, with silicone (Ecoflex 00-30) limbs, and PETG torso.

Design Motivation

This project was completed for a soft robotics course at BU. It scored 2nd place at an intercollegiate competition and won the fastest speed trial.

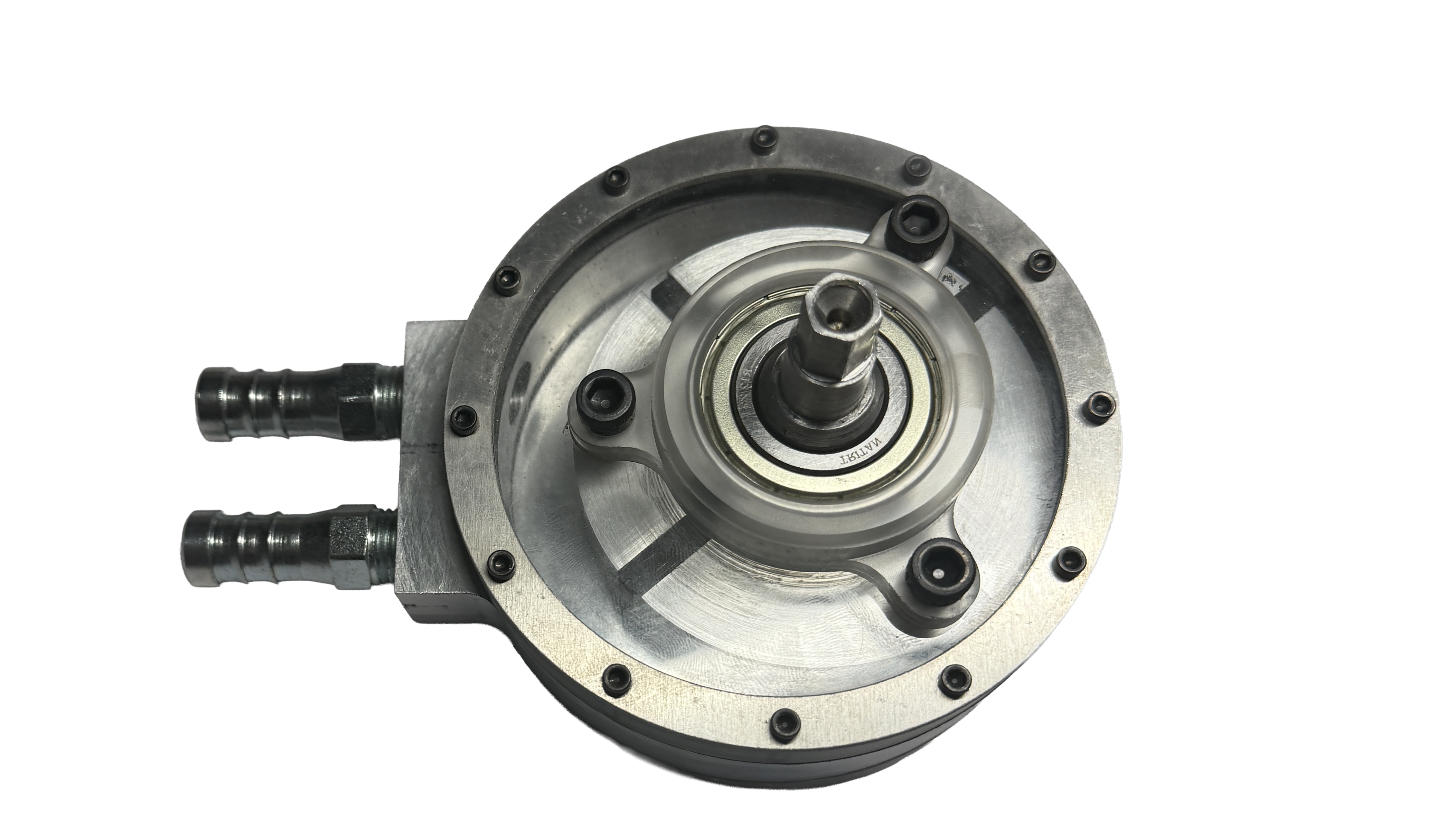

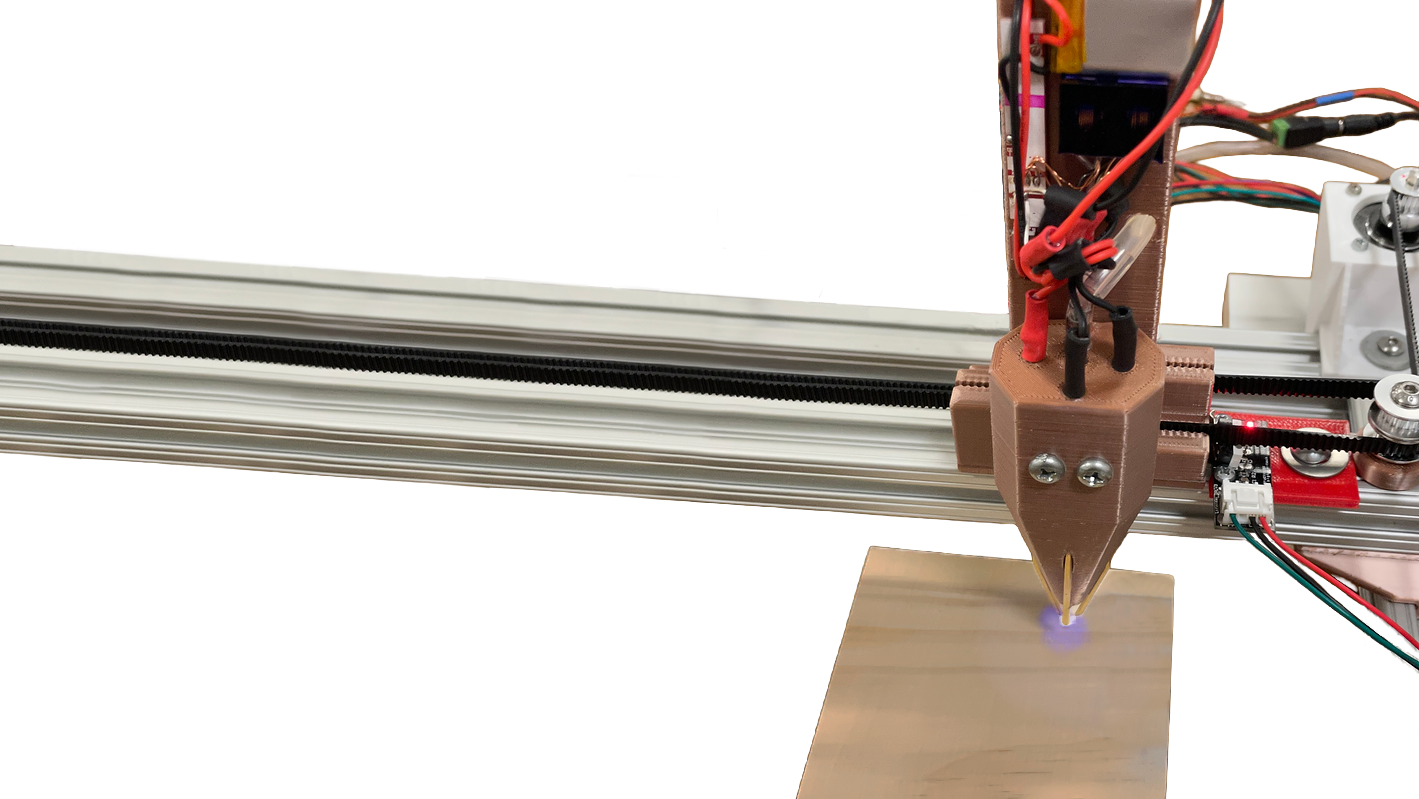

While many soft robots utilize pneumatics, fluidics, or dielectric shape memory alloys (SMA) for actuation, I was interested in the relatively unexplored mechanism of cable actuation.

Fabrication

Silicone Casting

Bench Testing & Controls

Tri-Hub Skeleton

Live Demo Video

Demo video of final operational robot featuring initial bench tests to validate both electromechanical control and forward, left, and right maneuvering capabilities.

Conclusions

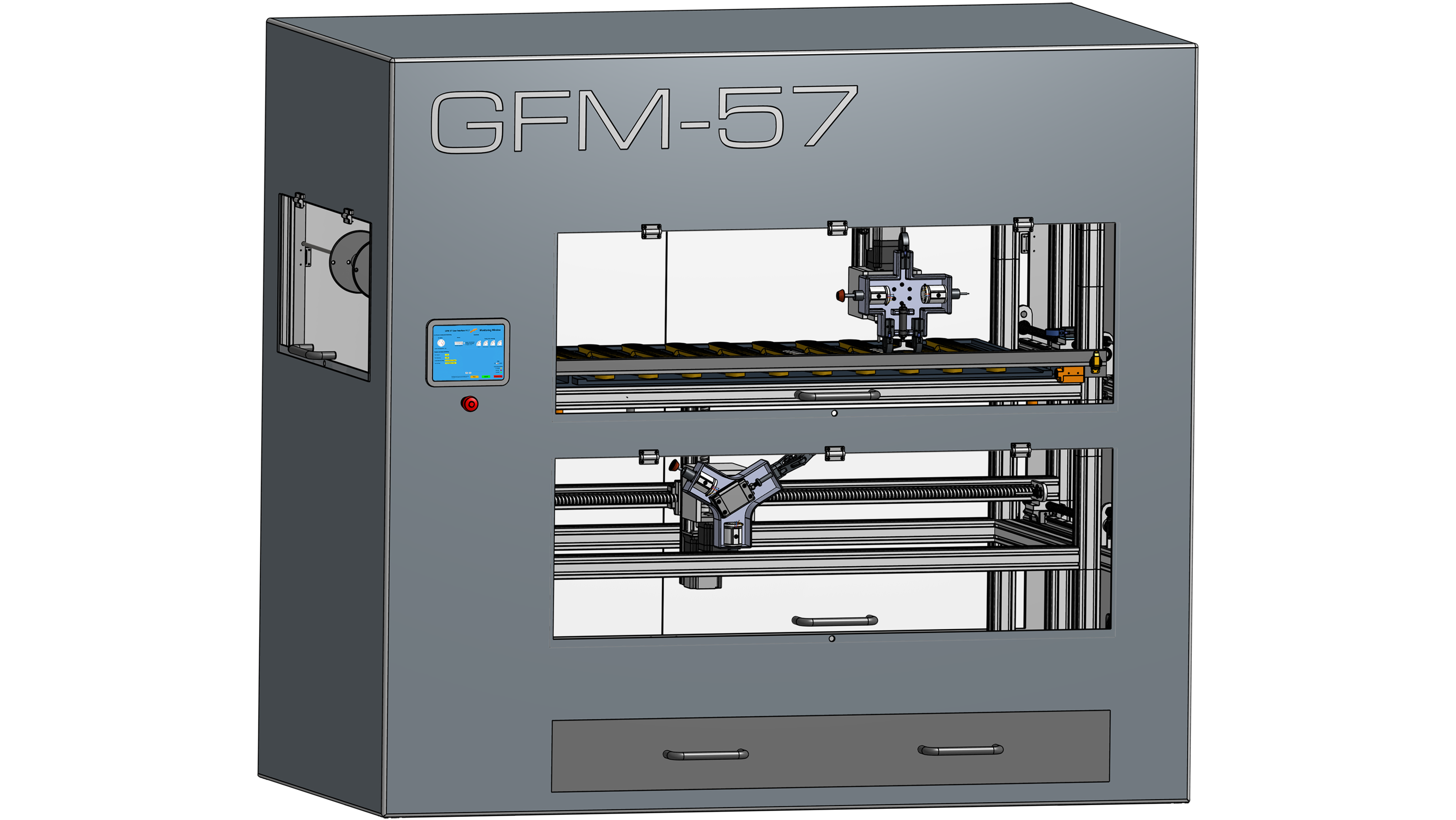

Full CAD rendering of final design (bottom perspective).

Full CAD rendering of final design (top perspective).

Applications for soft robots include medical robotics, biomedical engineering, and other use cases where robots come into close contact with human beings or other fragile projects, e.g. produce packing, harvesting fruits and vegetables, and so on. In these settings, soft robots can leverage their compliance to reduce risk to humans and other fragile objects they interact with. These same properties make soft robots promising candidates for navigating confined spaces, where traditional rigid robots would be unable to reach (such as in remote rescue operations, or space exploration).