Background

Design Objective

The purpose of this project was to design a fully-automated machine for fretting electric guitar necks.

Guitar fretting is a precise, multi-step process which includes milling 24 fret slots, pressing fret wire into the slots, cutting the fret wire, and finishing the ends of each fret so they sit flush with the neck profile

Problem Statement

The current industry standard is for skilled luthiers to perform guitar fretting manually, by hand. This is both time-consuming and labor-intensive. An automated precision machine that performs this process offers significant financial advantages to manual fretting, and offers a much higher throughput.

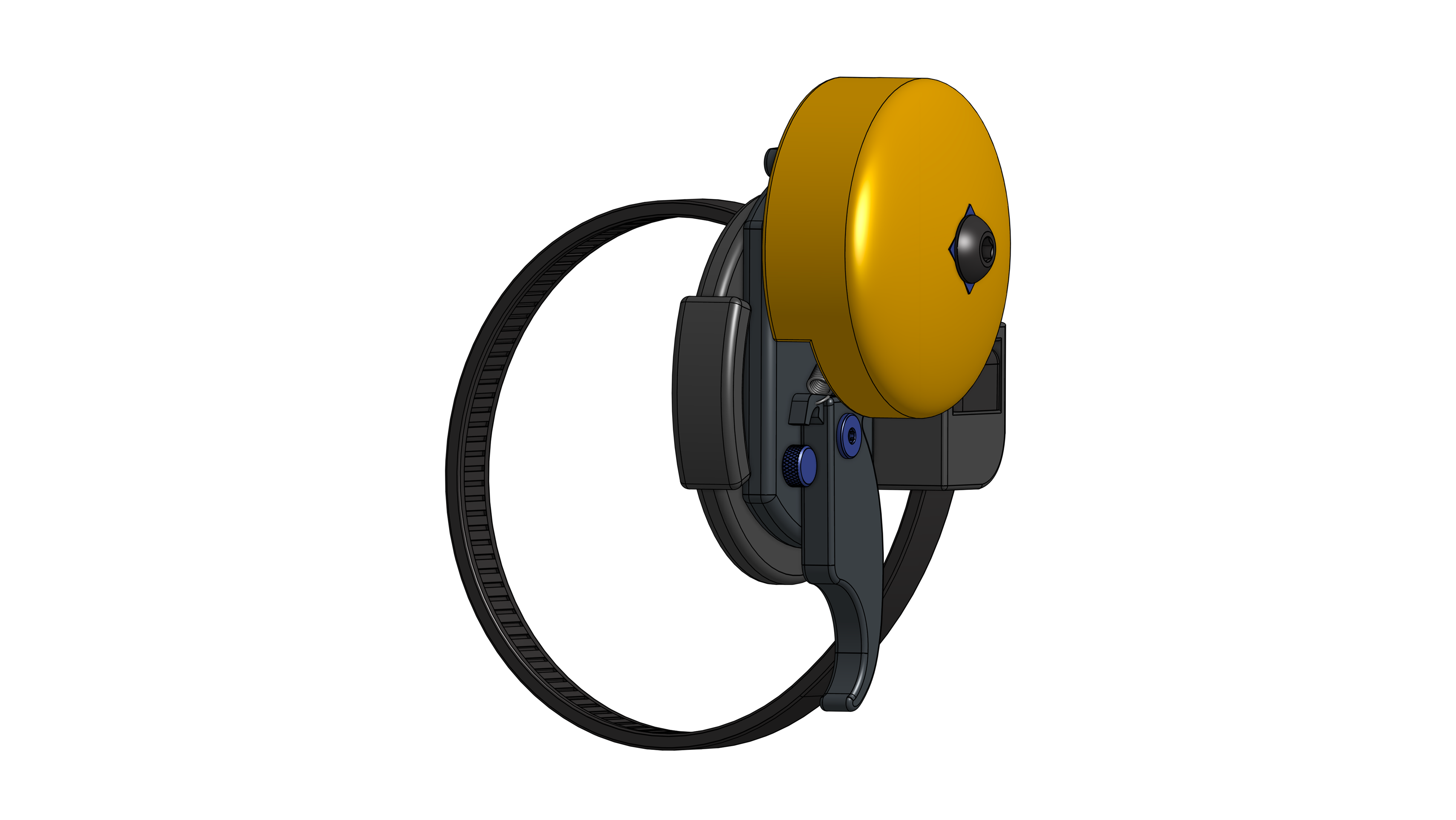

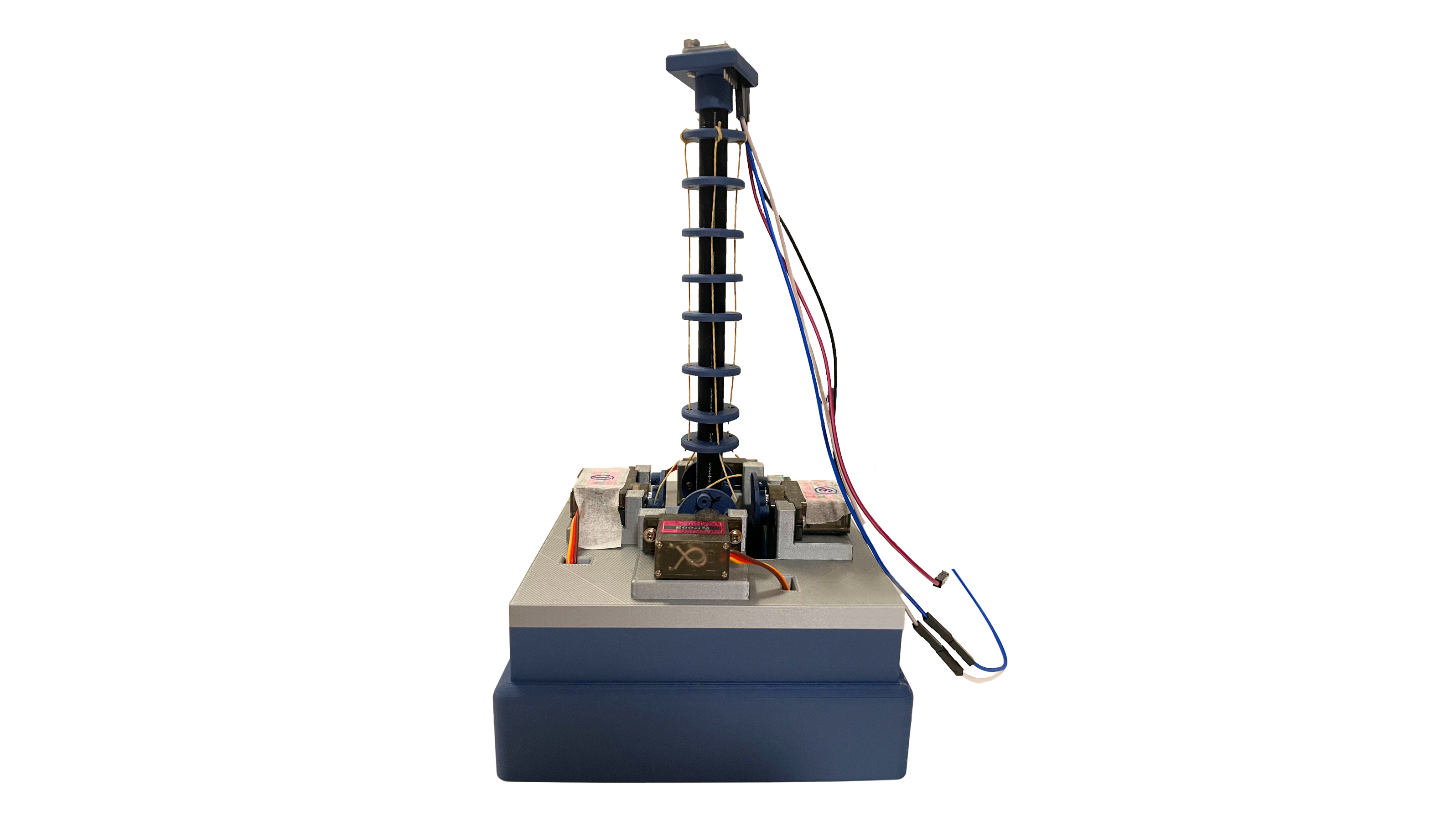

Top Tool Wheel (TTW) performing fret pressing

Machine Subsystems

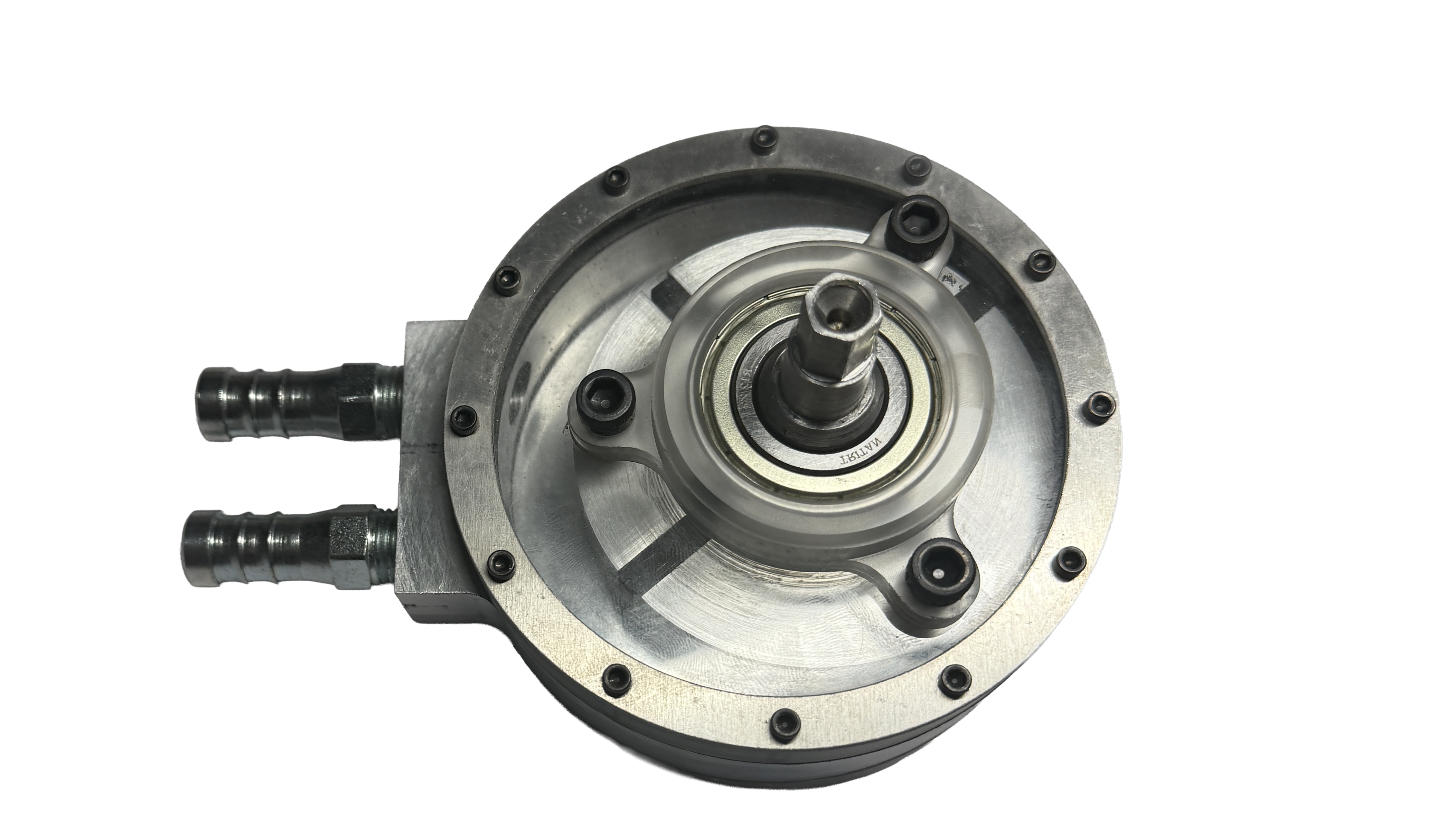

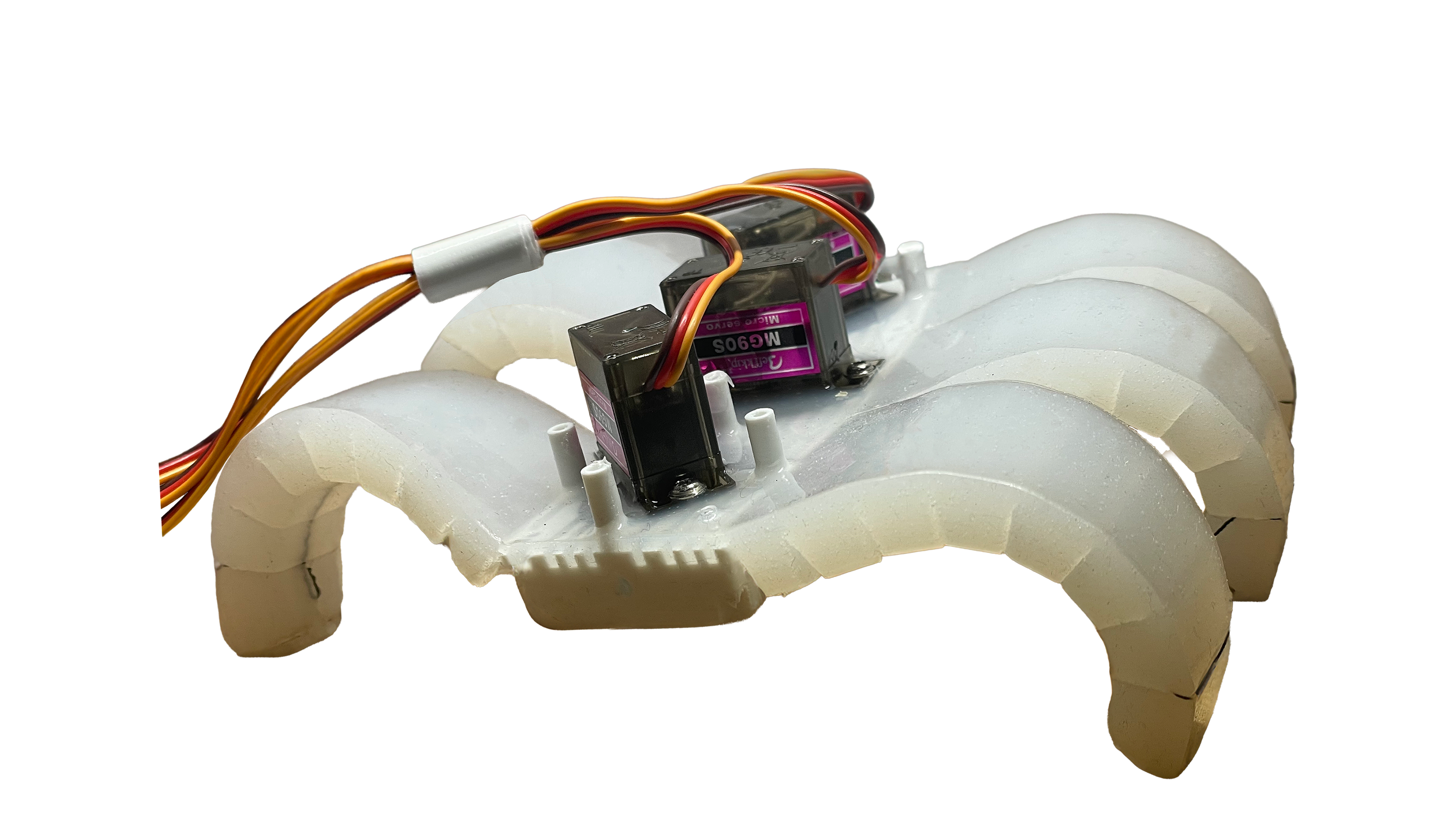

I. Eater-Feeder™ Fretting System

The Eater-Feeder system transfers the free end of the fret wire from the Feeder module to the Eater.

The gripper end-effector on the Top Tool Wheel (TTW) is used to perform this transfer, after which the Feeder module reverses to properly tension the fret wire. The fret wire supply spool is housed externally to the Feeder, which controls tensioning, feed rate, and alignment.

The Eater and Feeder then move in parallel to each other to position the wire length above the first row of ten frets, prior to pressing.

II. Top & Bottom Tool Wheels

Our design utilizes two rotary tool wheels, the Top Tool Wheel (TTW) and Bottom Tool Wheel (BTW).

These multi-purpose end-effector platforms cycle rapidly between tooling to perform each MFG process, while maintaining an efficient footprint within the build area.

The tool wheels perform some machining processes in tandem to minimize cycle time (see fret grinding below).

III. Neck Rack

The removable neck rack can accommodate guitar necks with varying scale lengths, radii, and fret board widths.

It achieves this through the use of adaptive retaining mechanisms, such as proximity sensor-equipped pneumatic grippers with compliant surfaces.

Machining Process Overview

I. Batch Set Up

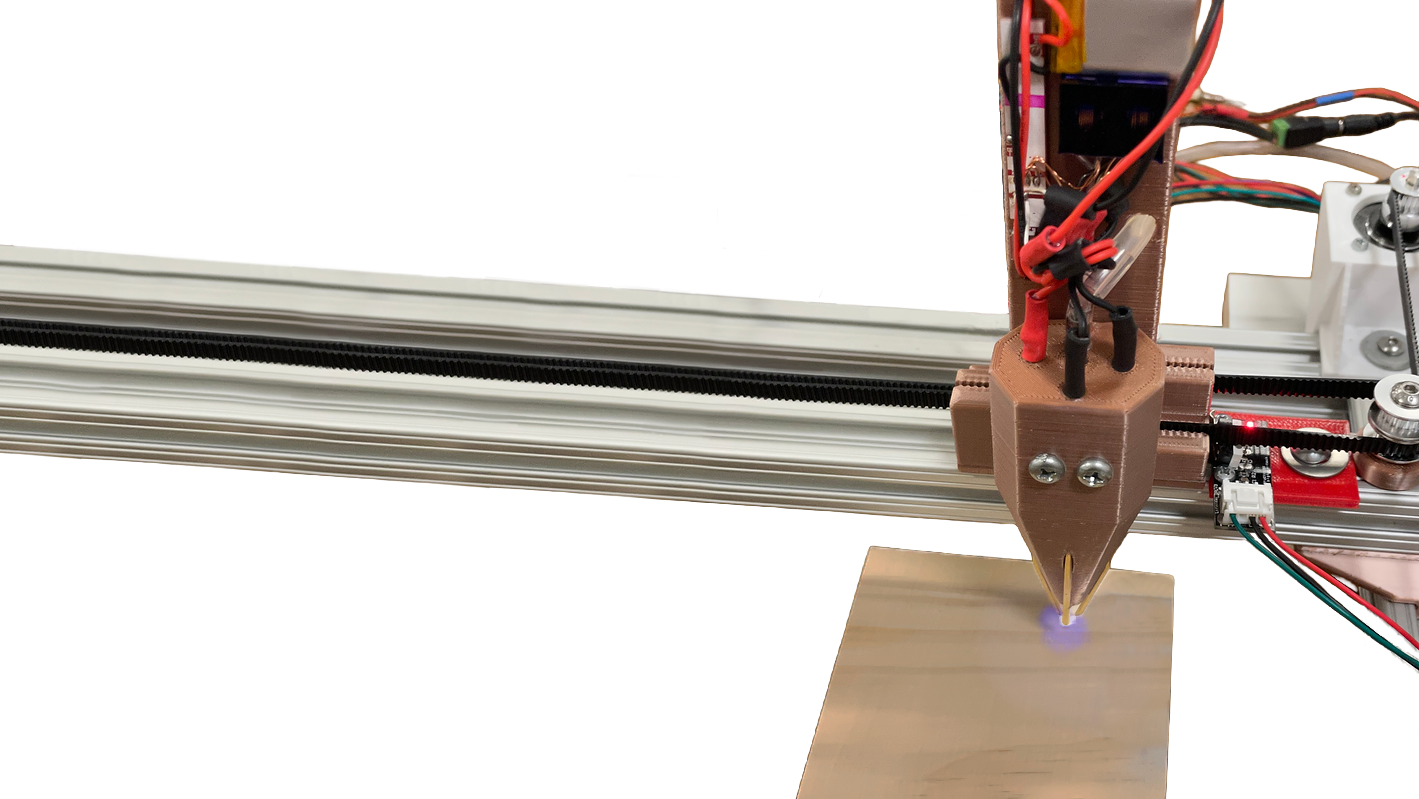

II. Fret Slot Milling

III. Fret Wire Pressing

IV. Fret Cutting

V. Fret Grinding & Polishing

The GUI (Graphic User Interface) Batch Monitoring window provides information on the current cycle status, end effector RPM, % tooling life remaining, and expendable supplies.

VI. Batch Monitoring

Flow Chart: Controls & Hardware

Financial Justification

Our proposed design has a 5-year NPV (net present value) of $4.7M, and a 6-week payback period, making it an excellent investment.

A PDF with the complete presentation for this project, including detailed financial justification tables (see appendix), motor torque calculations, and other details not presented on this page can be downloaded below.

Several core contributions I made to this project were:

• Design of the top and bottom rotary tool wheels and their associated end-effectors

• Creation of the detailed flow chart for hardware, controls, and sensing operations

• Design of the graphic user interface (GUI) in MATLAB