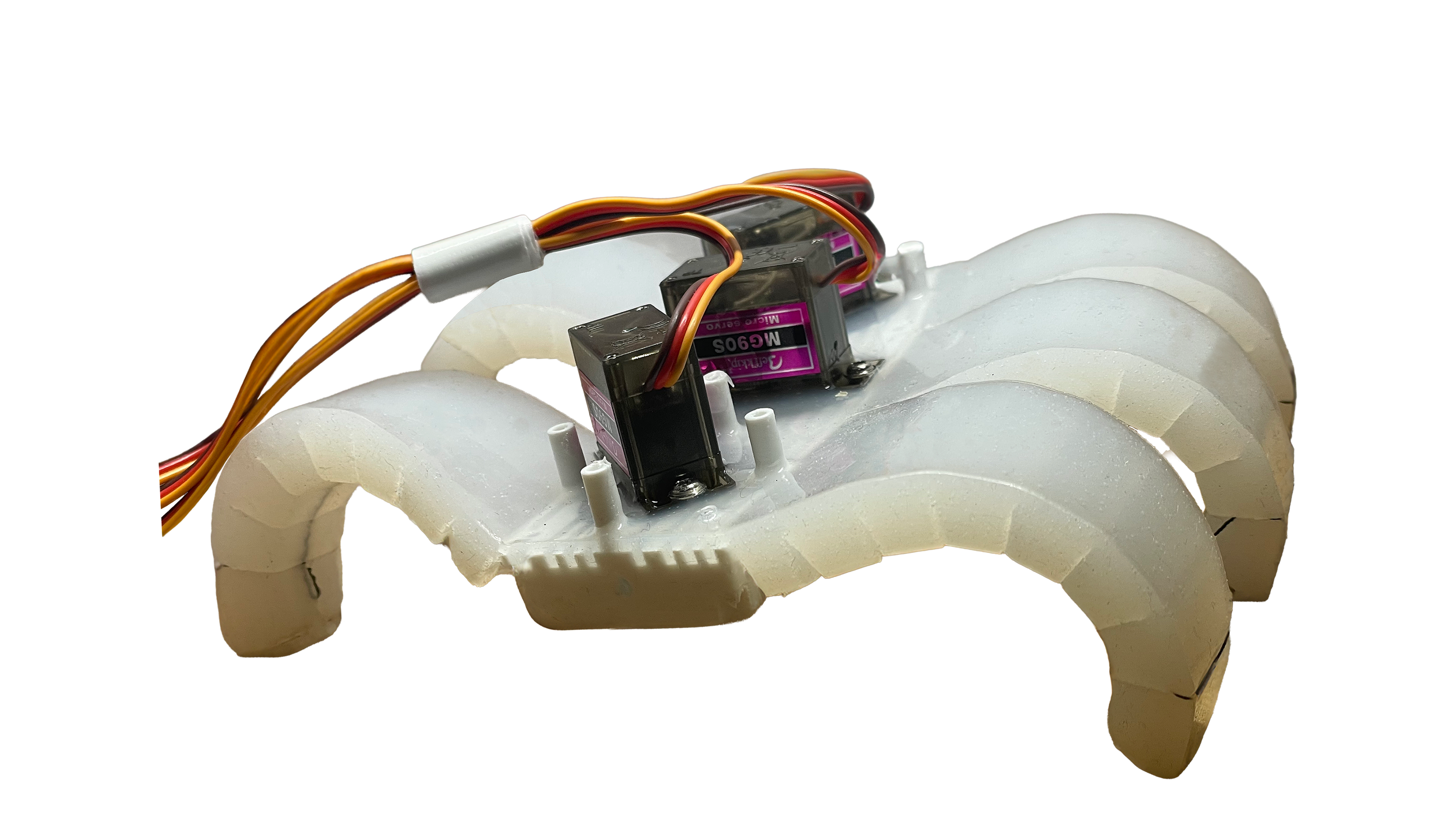

Pump components prior to first dry assembly

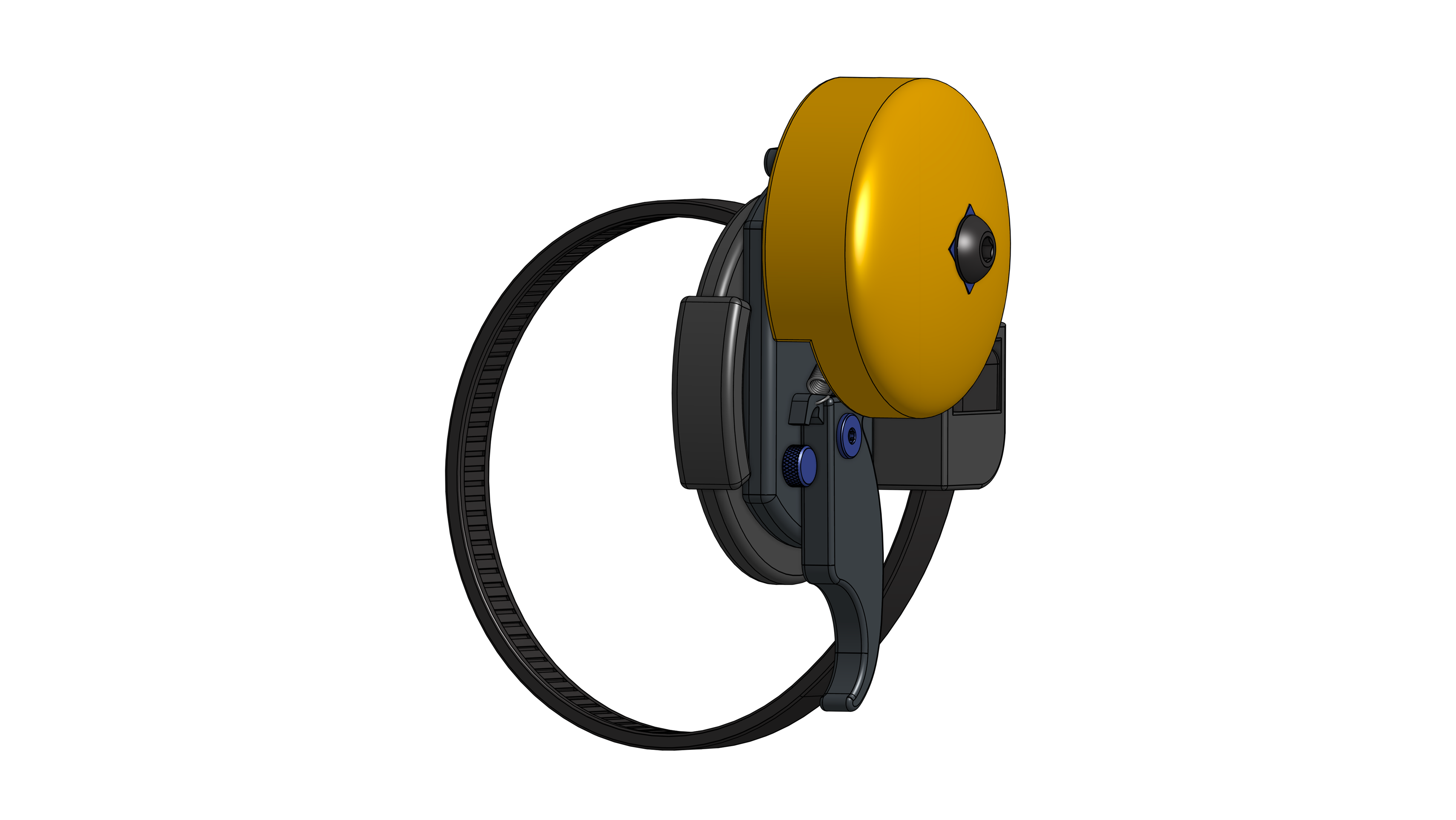

Fully-assembled prototype

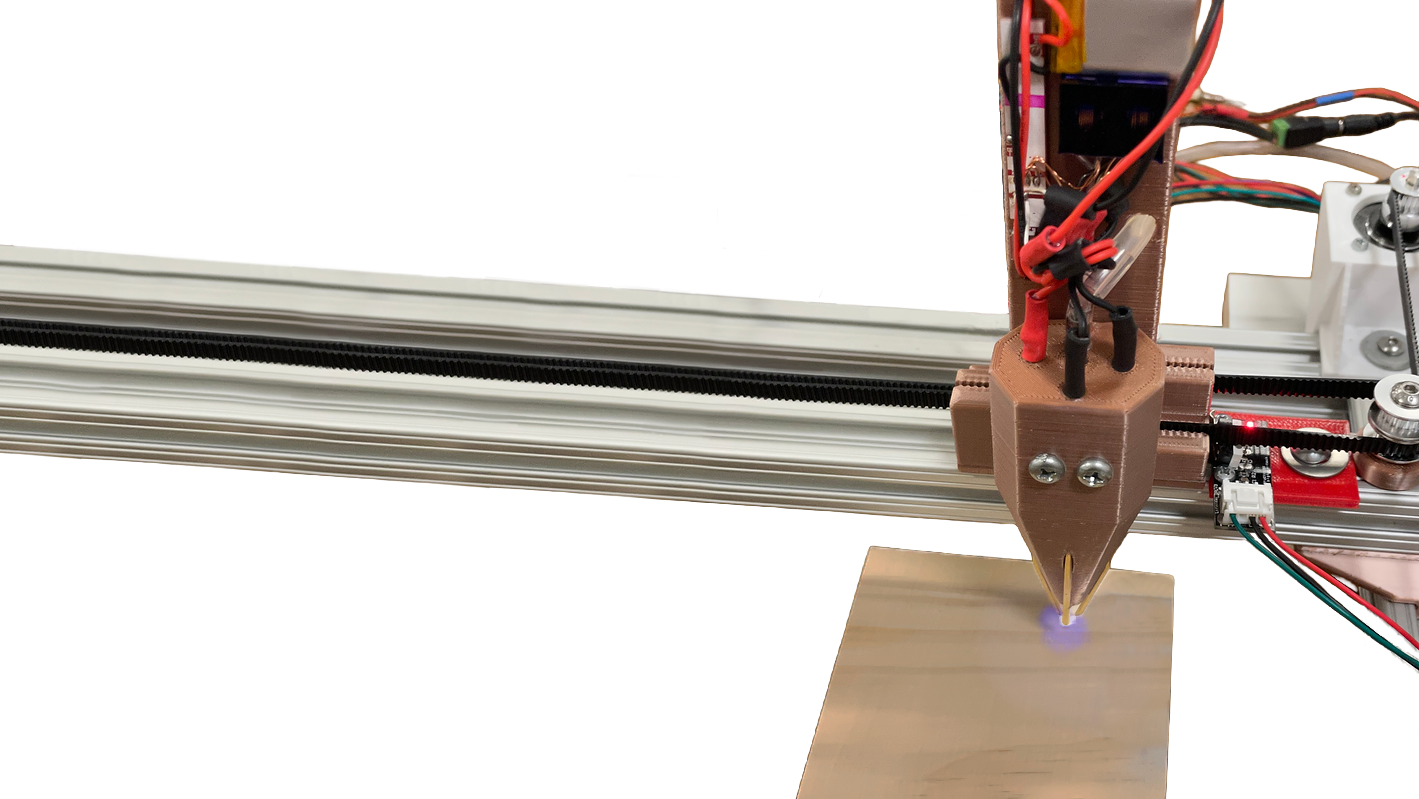

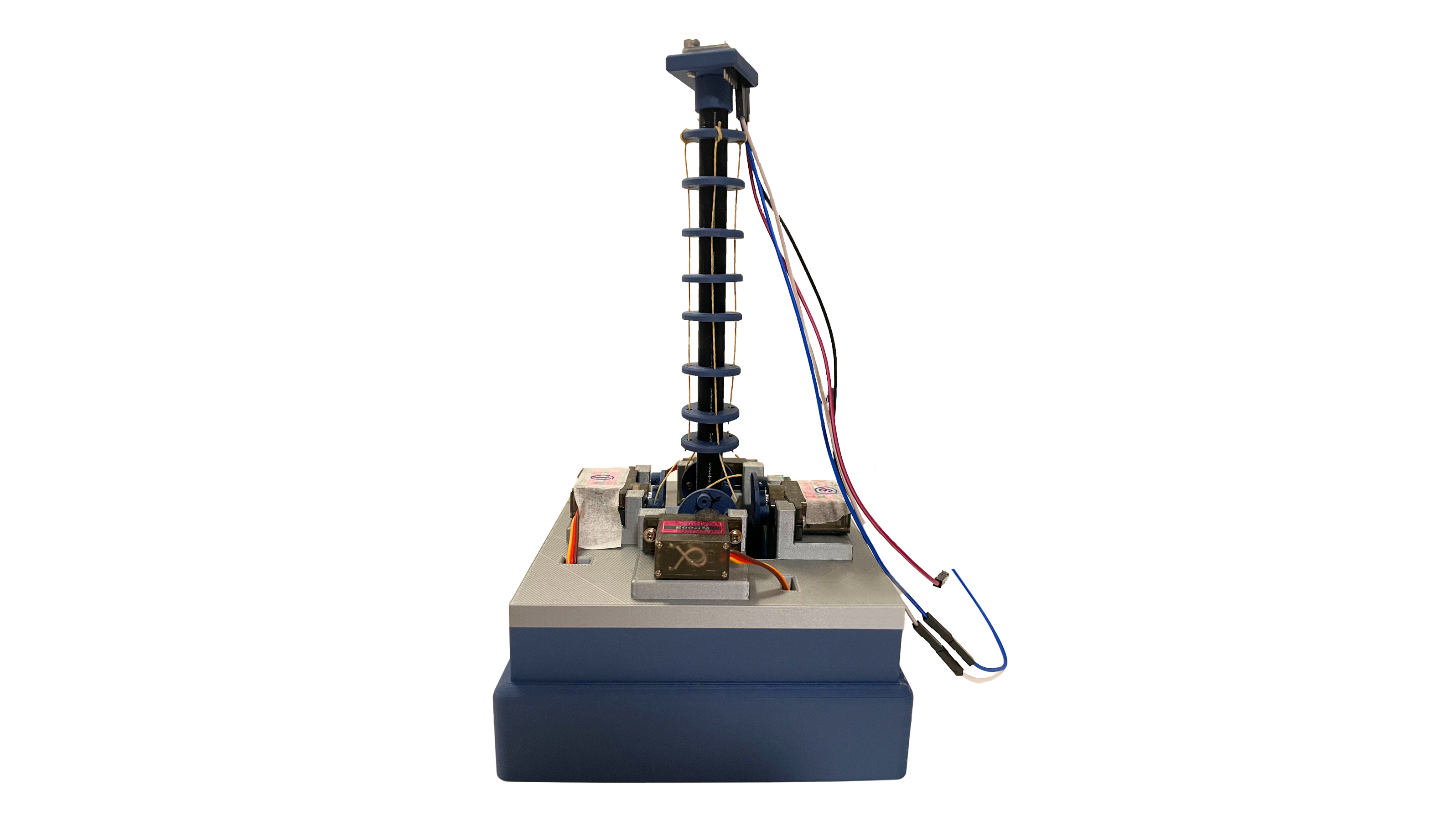

• CNC • 3-axis end mill

• Water jet cutter • Sand casting

• Injection molding • Shrink fitting

Footage of sand casting the bearing housings in aluminum

Machining of housing during an interrupted cut on the lathe

Footage of CNC milling of vane slots into rotor after turning on lathe

Post-processing of sand cast bearing housings with band saw

Milling of inlet & outlet holes prior to tapping and installation of threaded fittings to housing

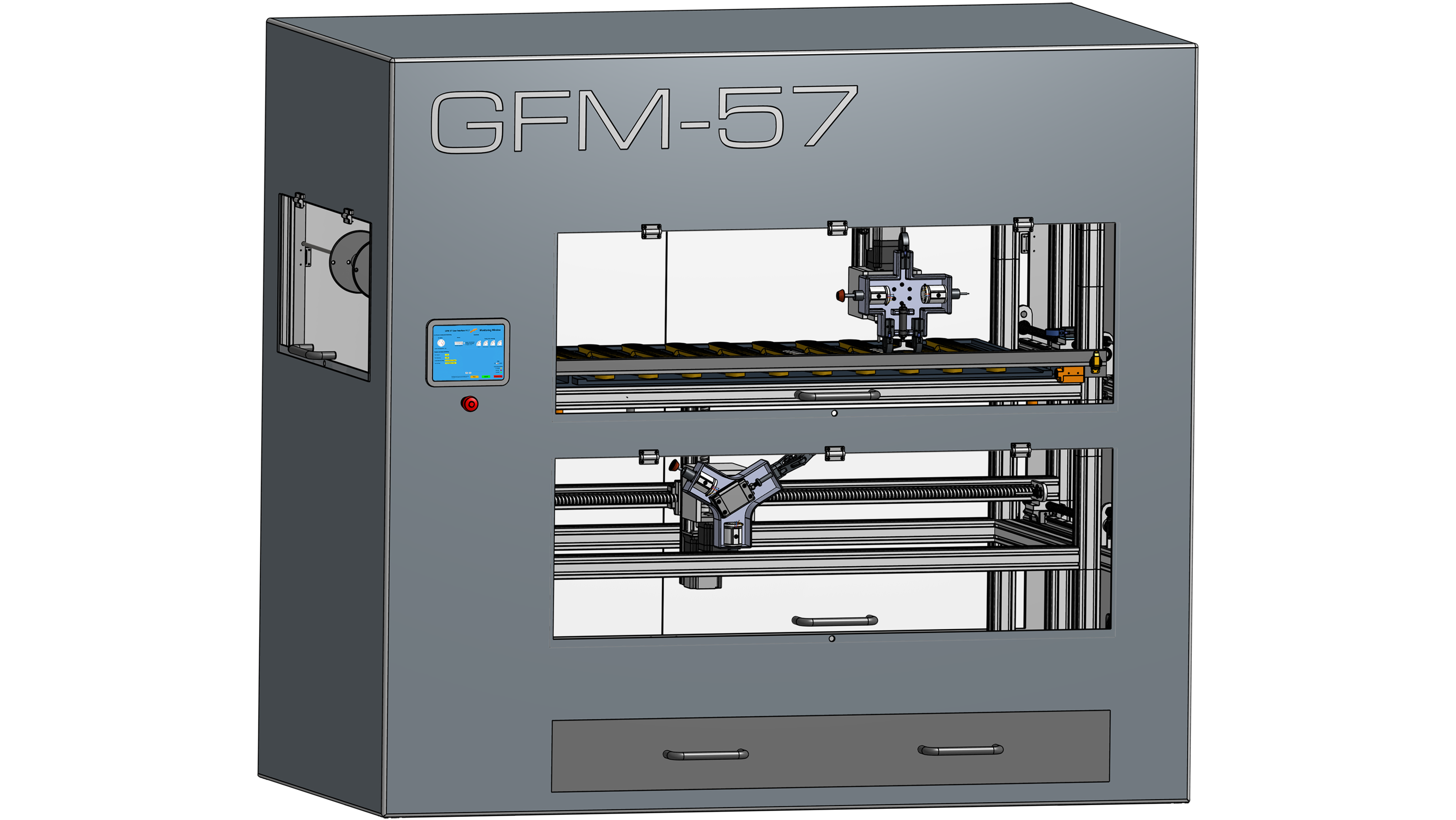

CAD rendering of pump redesign

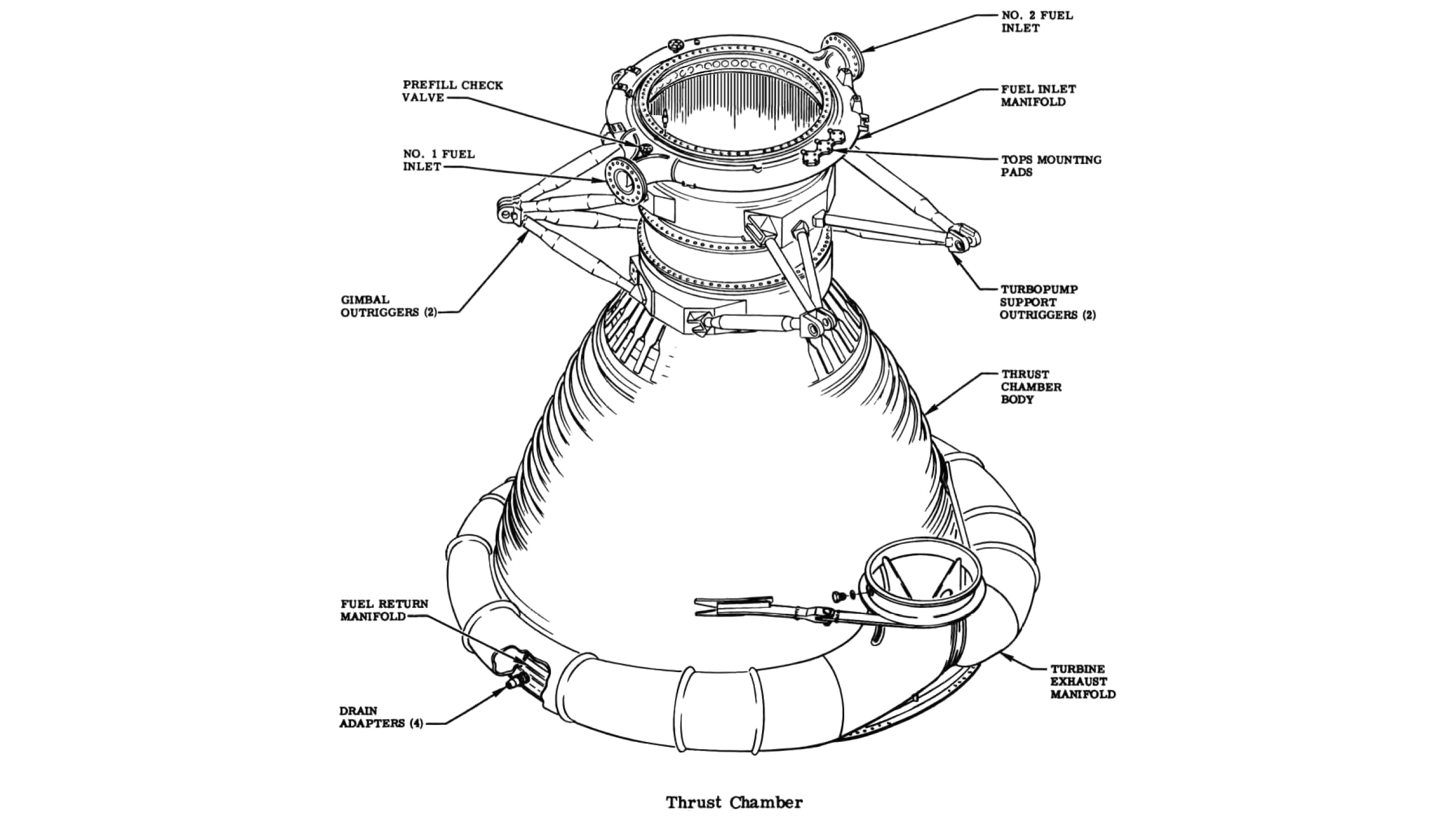

Exploded drawing view of full assembly

GD&T drawing of housing for machining post-casting

Infographic highlighting several design modifications made to housing

Simulated design specifications for pump redesign

Parting line drawing for housing casting

Summary table of design modifications and their justifications