Individual Contributions

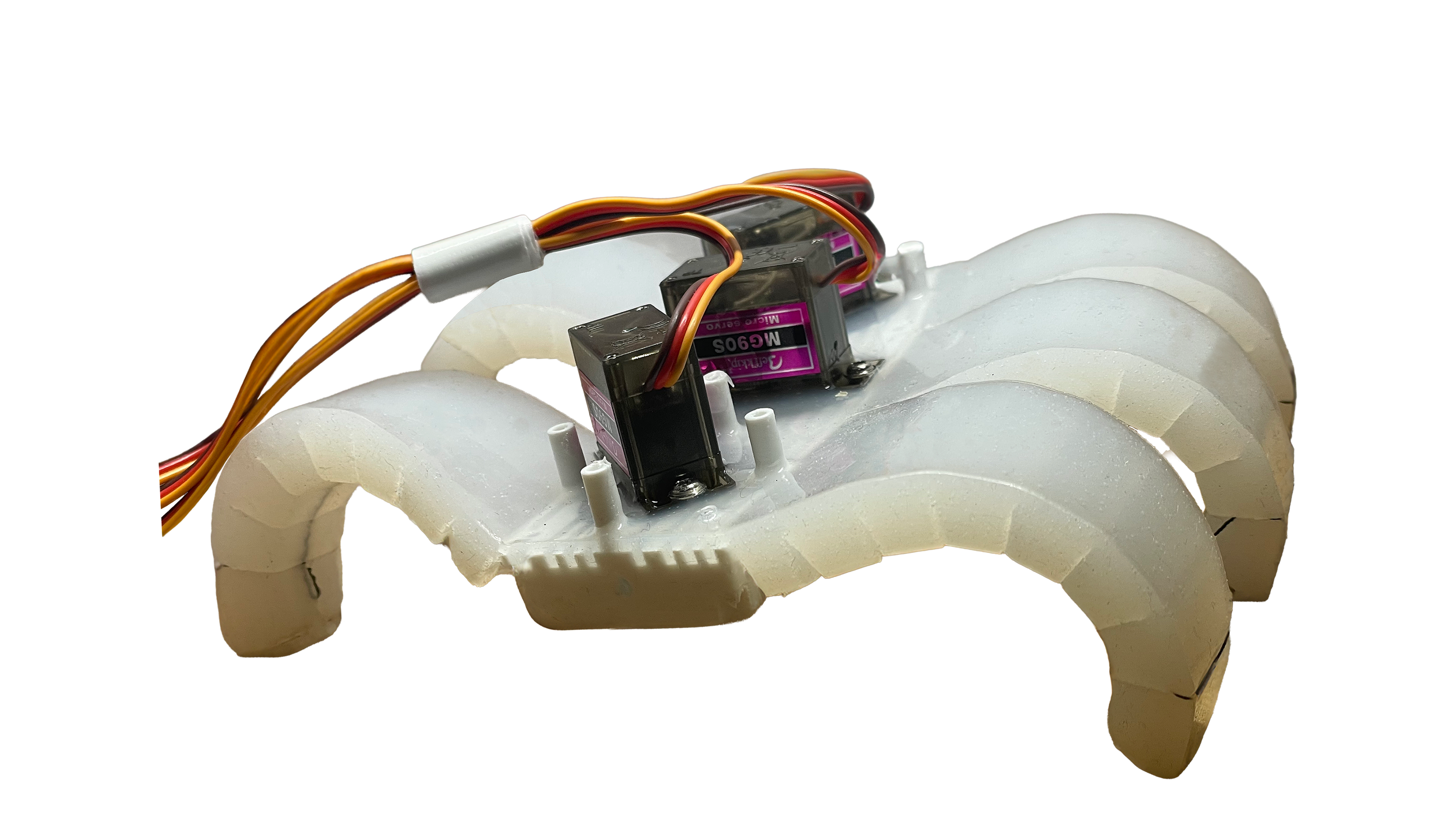

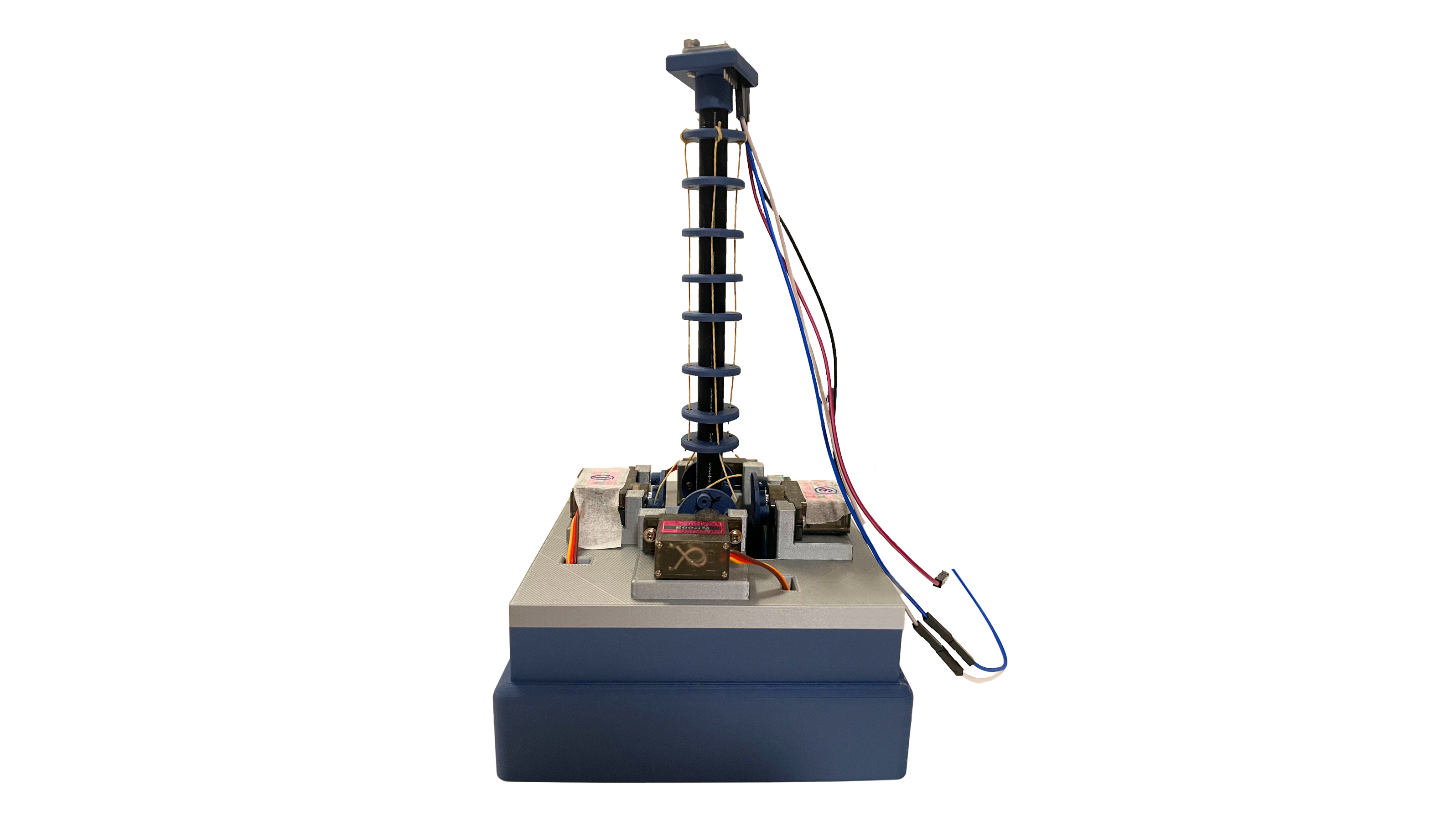

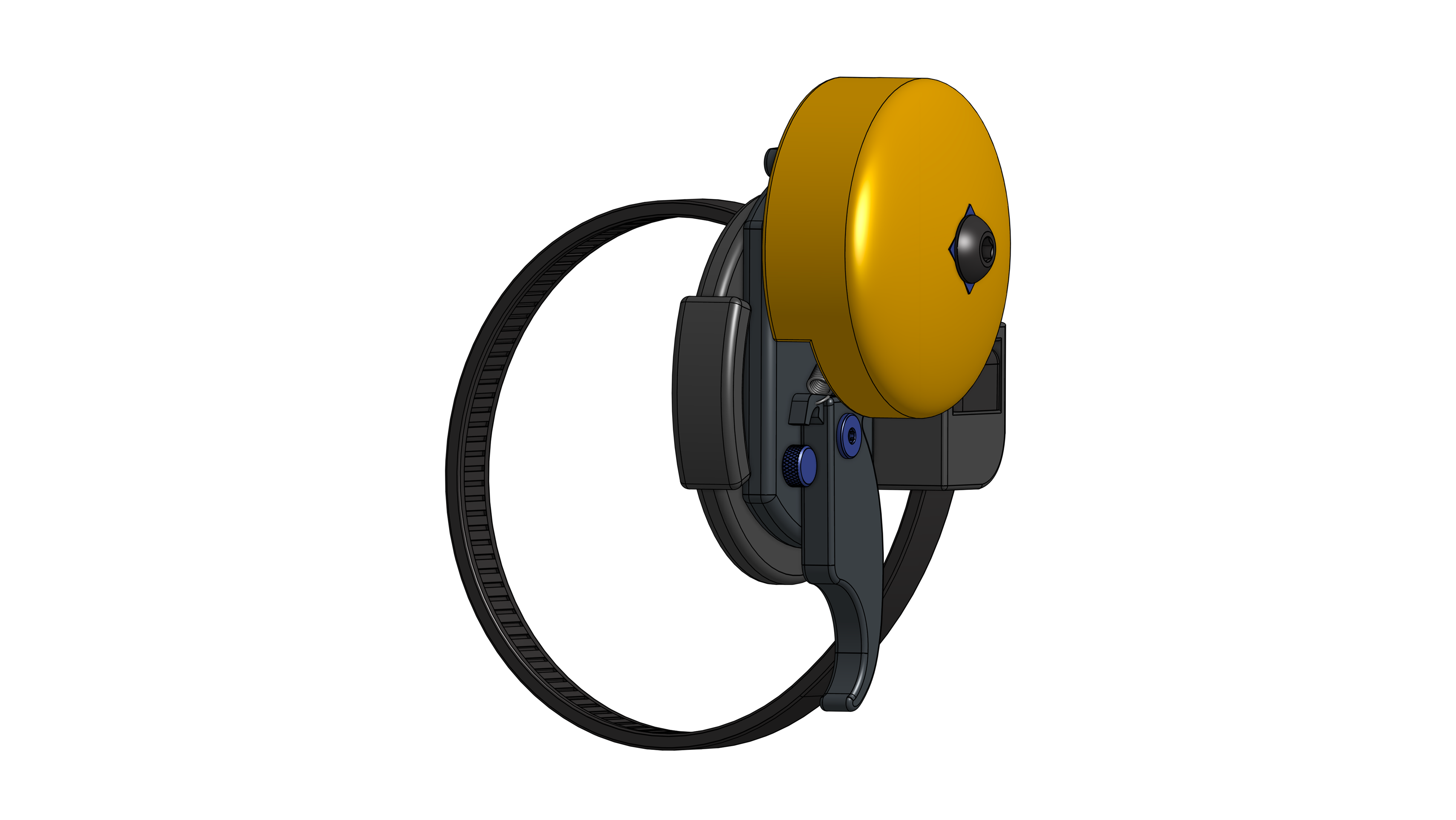

• I was responsible for the complete electromechanical design and fabrication of the end-effector, including component selection, CAD modeling, and the associated electronics/wiring

• I collaborated with group members on the design and assembly of the CoreXY linear motion system and its associated hardware (linear rails, limit switches, stepper motors)

Background

Design Objective

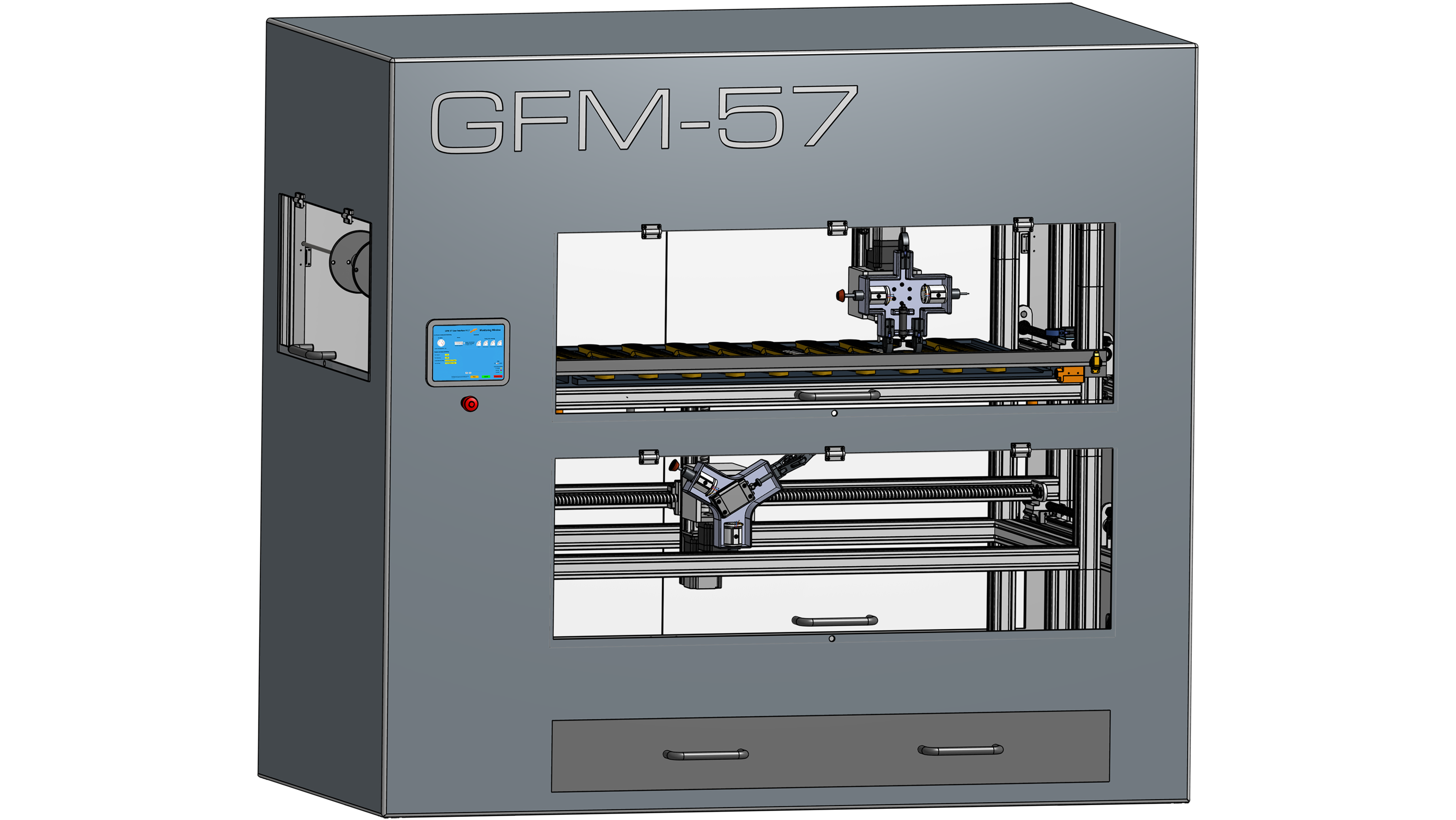

This group project was completed for an electromechanical design course at BU. The broad project requirements were to design and fabricate a 2-D motion system with 2.5 degrees-of-freedom (DOF). The first two DOF corresponded to X-Y motion in the 2-D plane and the 0.5 DOF to the selected action of the end-effector.

Design Overview

Our team chose to build a Core-XY motion system instead of the conventional cartesian "bed slinger" system, as we felt it would be more of a challenge. Core-XY also affords greater speed, accuracy, and build volume relative to footprint, when compared to cartesian systems.

Demonstration Video

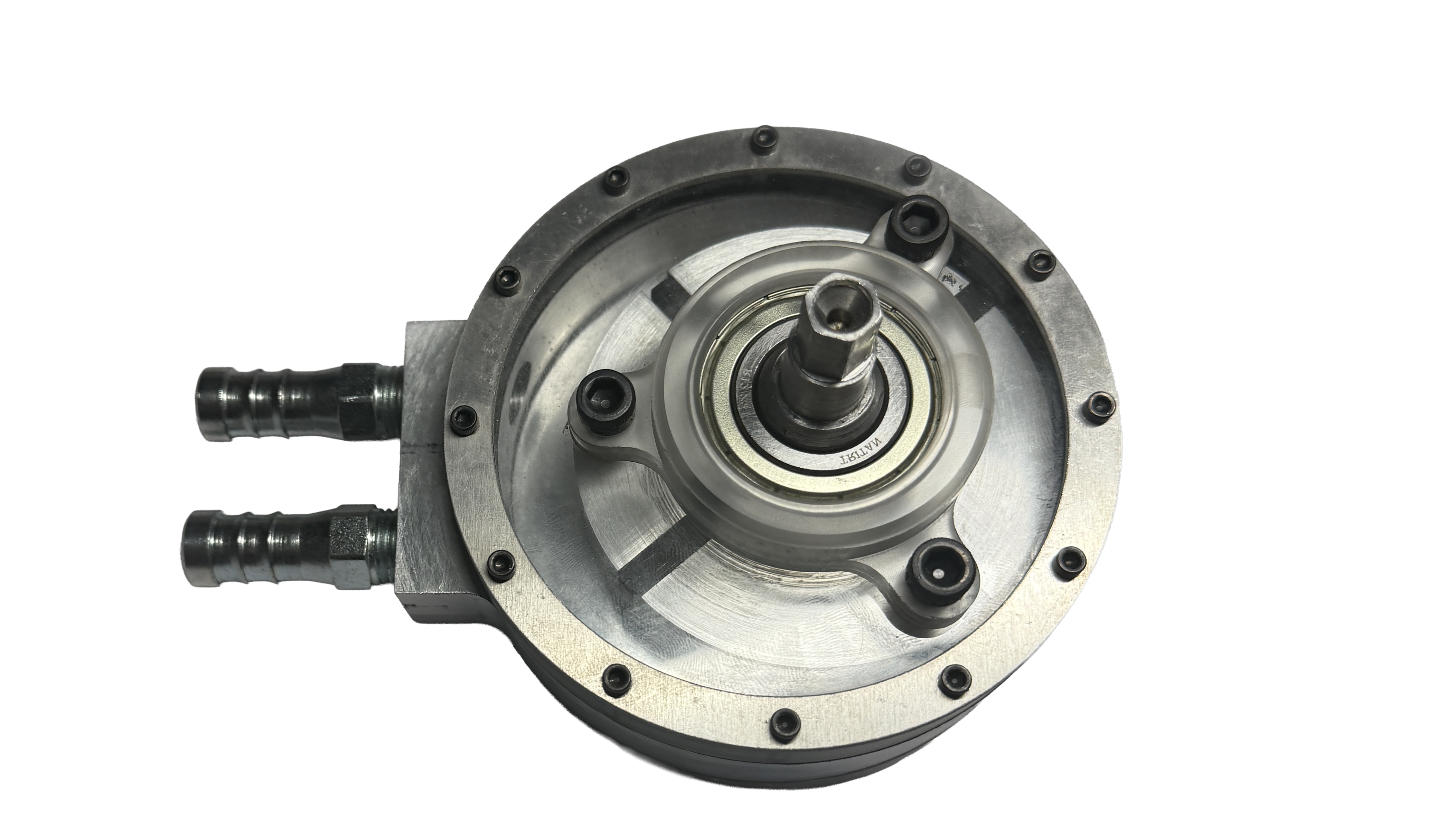

Plasma Burner Operating Principles

A flyback transformer was used to produce the plasma, which arced between four pieces of brass rod — two anodes and two cathodes. The transformer was controlled via a relay, which was energized by an L298N dual H-bridge. The second H-bridge was used to cycle the compressor on/off in tandem with the transformer. The compressor's purpose was to direct the plasma arc down to bed-level.

An Arduino was used as a microcontroller, such that plasma, directed by air from the compressor, could burn a programmed 2-D pattern onto the wood canvas.

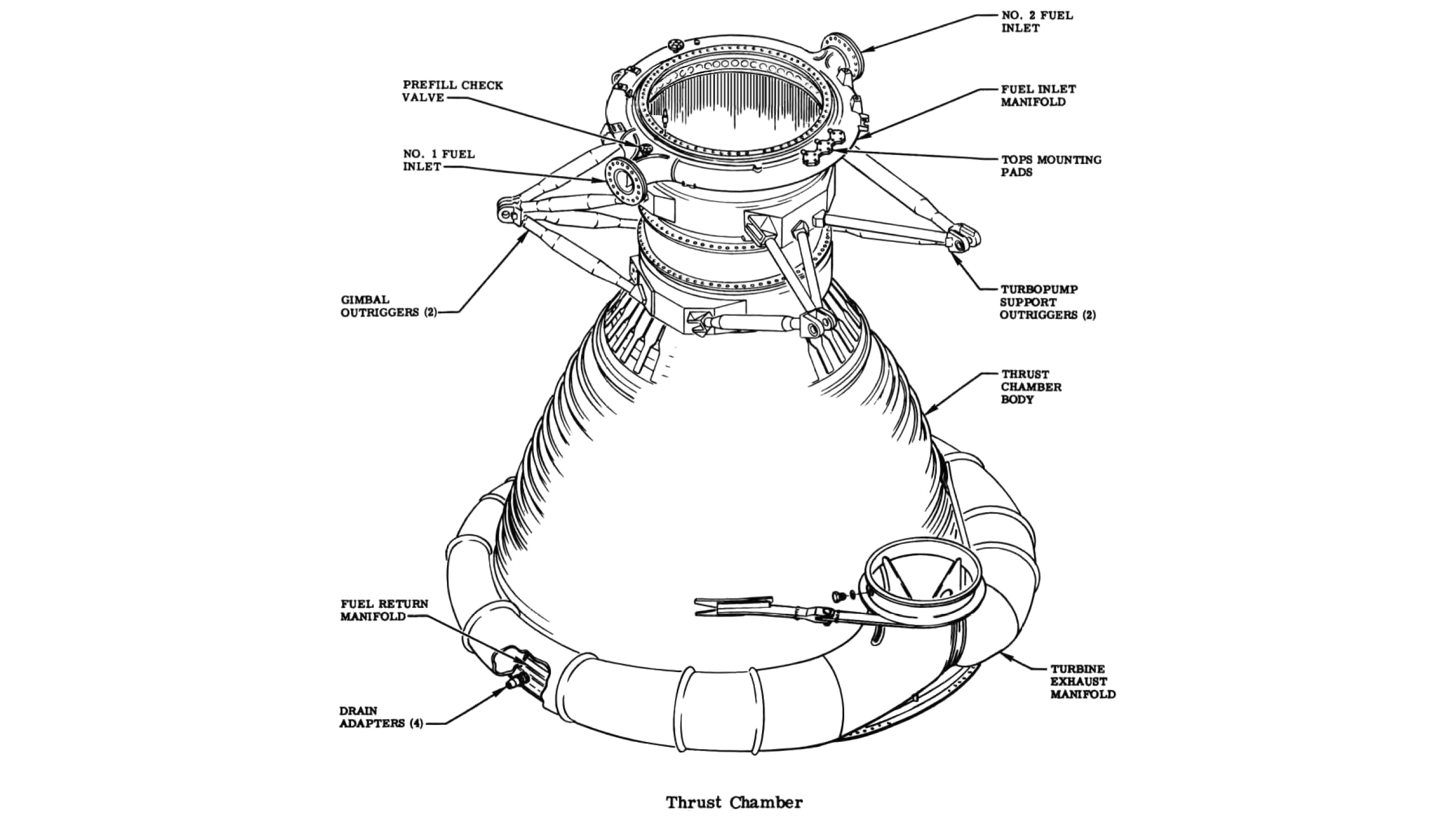

Early concept sketch of the system

Initial fabrication of the end-effector on the bench