Problem Statement

During the period of this product's design and sale, the TPE insulation used in iPhone charger cables was prone to failure due to repeated strain from normal use. This failure ultimately resulted in loss of core conductivity and thus charging function. For the consumer, this meant expensive (~$25) replacements and needless electronic waste. There were approximately 1 billion iPhone users worldwide in 2020. Given the ubiquity of smartphones, the motivating principle behind the Cable Collar’s development was that critical accessories — such as charger cables — should not be regarded as consumables, at least not on the timescale implied by their current, insufficient longevity.

Design Objectives

The main design objective was to create a simple, cost-effective solution for extending the functional lifespan of smartphone charging cables.

A secondary design objective was to provide ergonomic improvements for disabled or less-abled users. To achieve this, two specific aims were identified: improving fine-motor manipulation of the cable during insertion into a phone’s charging port, and securing the cable’s free end to a fixed point that remains within reach for users confined to bed or with limited ability to bend down to retrieve a cable from ground-level.

One three-pack of Cable Collars as sold in recycled packaging

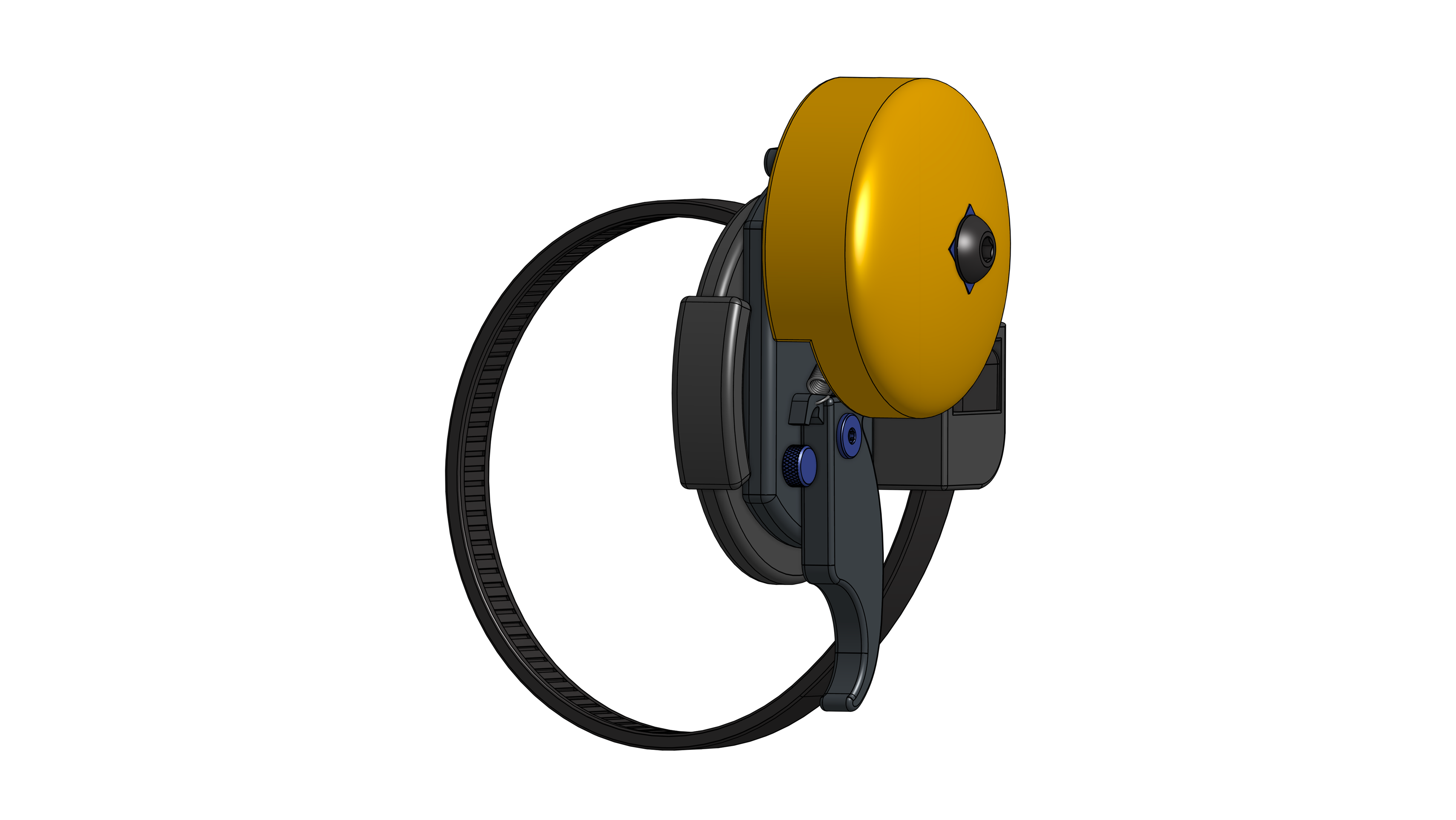

The Cable Collar was designed to have minimal parts in order to optimize it for in-house production. It consists of three primary components:

[1] The main red sheath is composed of dual-walled, adhesive-lined, polyolefin tubing. This material is heat-sensitive and contracts up to one-fourth of it's original diameter when exposed to heat.

[2] A section of polished high-carbon steel is affixed to [1]. This highly-ferrous metal securely mounts the charger head to the magnetic cable docks at a chosen location. It also serves as a brace to prevent bending at the most common failure point of the OEM cable.

[3] Two white polyolefin collets are press-fitted onto each end of the assembly, securing [2] to [1].

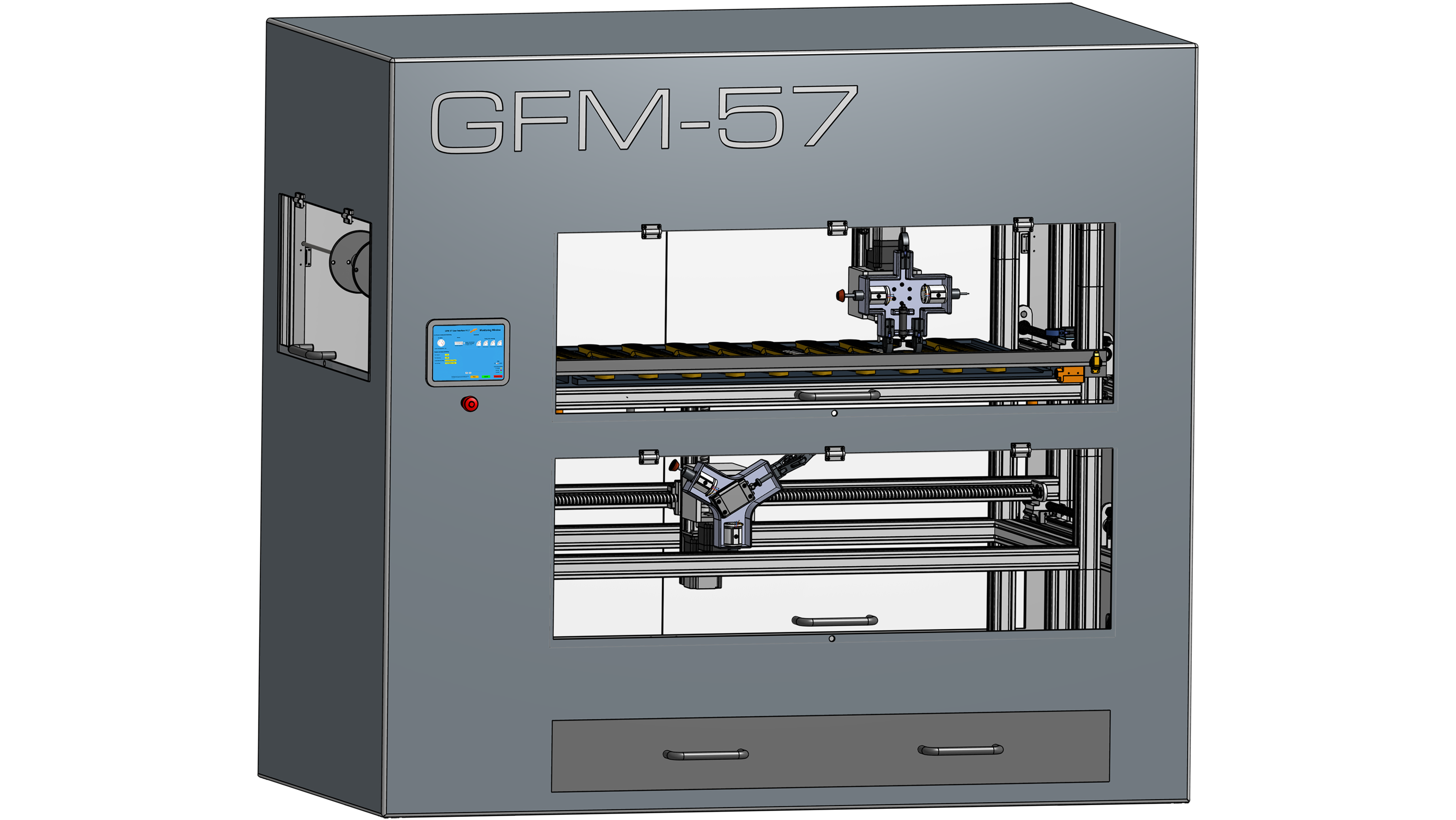

Manufacturing Automation

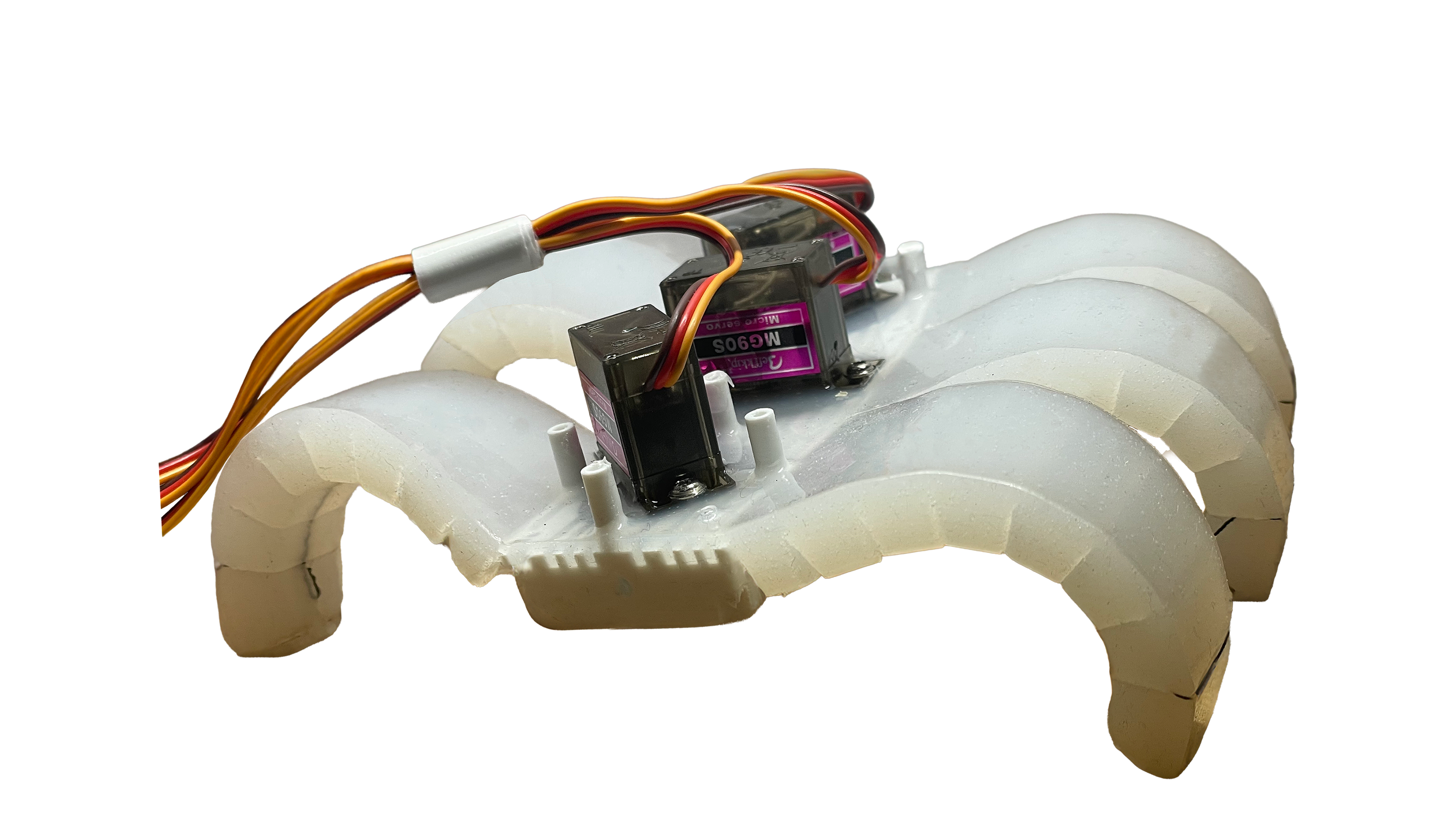

One major engineering design challenge resulted from the goal of in-house production. To meet consumer demand for the product, automated production methods were developed. The unique material properties of the polyolefin components presented challenges.

The white polyolefin collets require a precise ID in order to be press-fitted onto the main red sheath. This ID is not produced by manufacturers. As such, the collets must be pre-shrunk to the required ID, prior to installation. This requires that they are exposed to heat for a specific time, while being rotated to ensure even contraction. Overheating will also result in melting of the adhesive lining, which should not occur until the time of user installation.

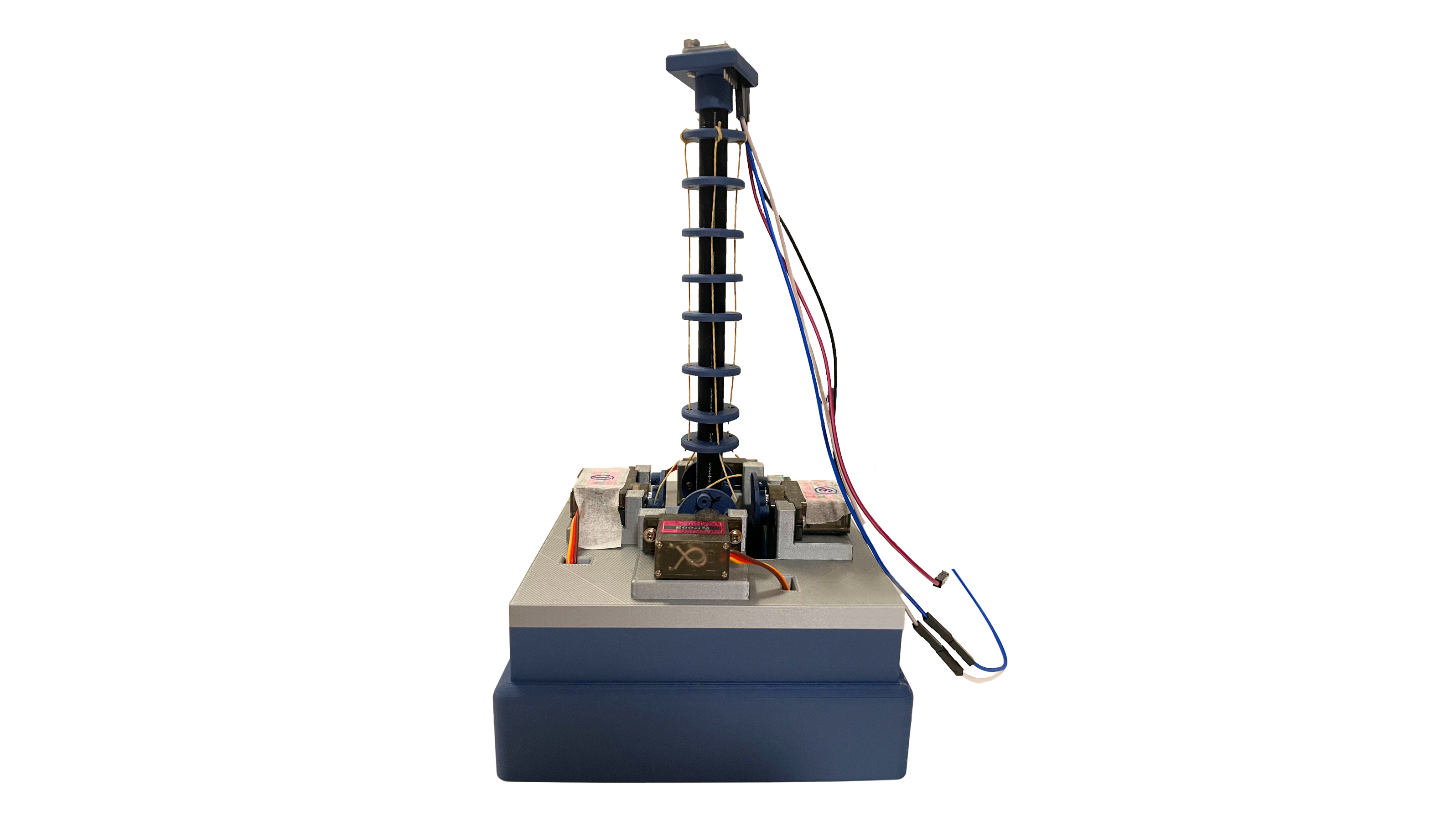

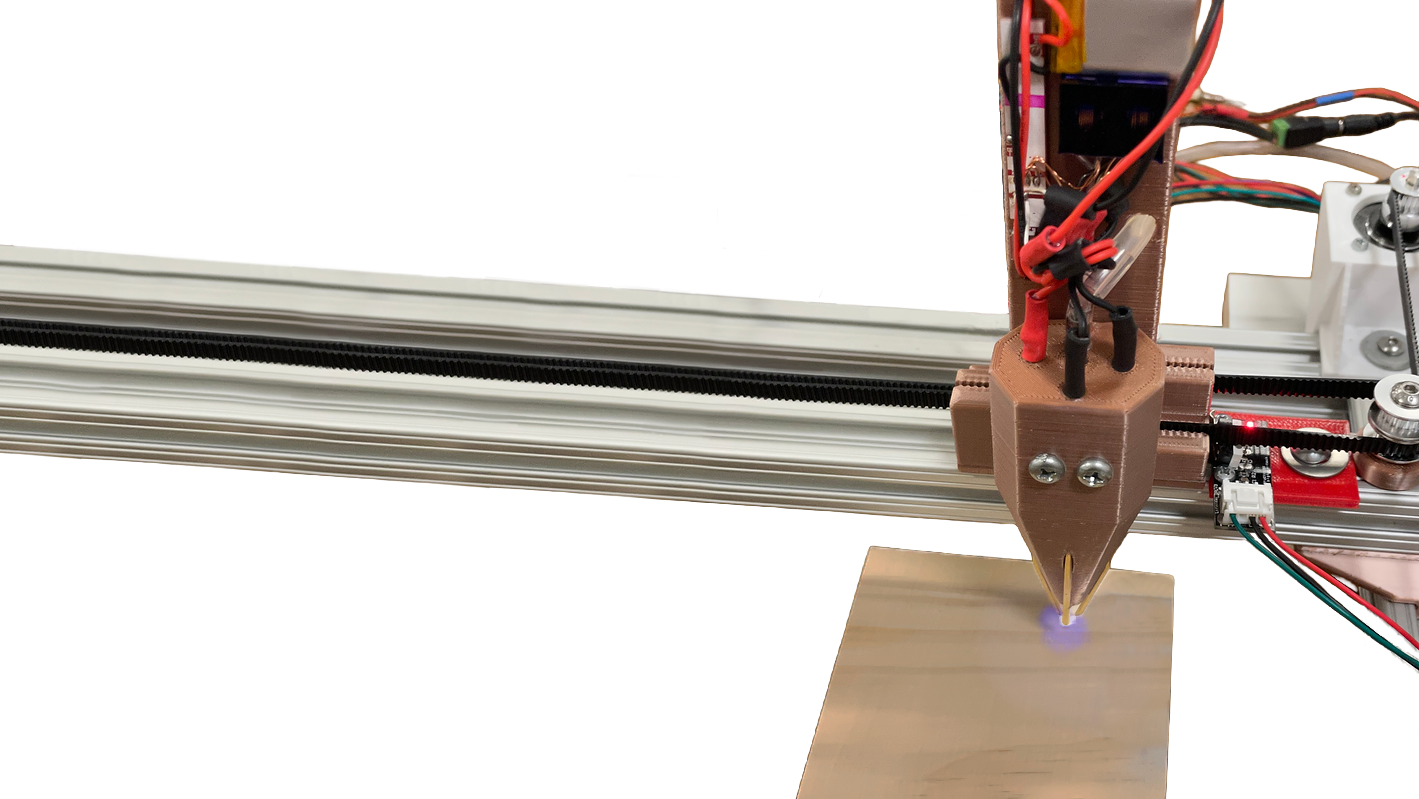

I designed a machine to facilitate this process, which is demonstrated in the video at the right of this section.

Demonstration video of automated collet machine

Documentation of product's success on Amazon

The Cable Collar proved successful within an e-commerce setting. It earned the "Amazon's Choice" designation within several product categories. A customer base was established across 46 states, in addition to the UK, South Korea, and UAE.

Ultimately, challenges in scaling the business, including the significant time investment required to handle both production and marketing by myself led me to retire the product.