Background

Design Objective

The purpose of this project was to design a fully-automated machine for fretting electric guitar necks.

Process timing calculations for our proposed design show that it has a 5-year NPV (net present value) of $4.7M, and a 6-week payback period.

Problem Statement

This process, normally performed by skilled luthiers, is both time-consuming and labor-intensive. An automated precision machine that performs this process offers significant financial advantages to manual fretting, and offers a much higher throughput.

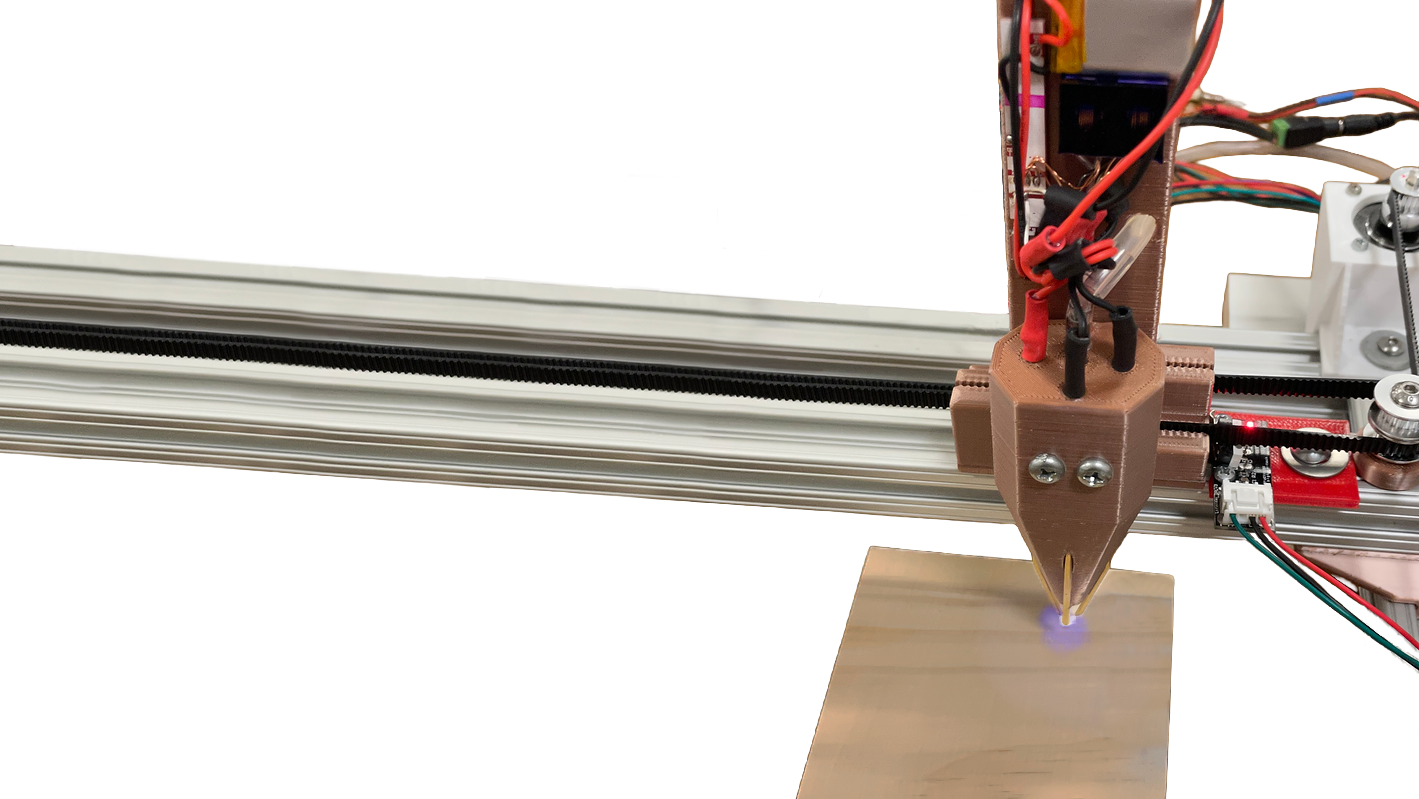

TTW performing fret slot milling

Machine Subsystems

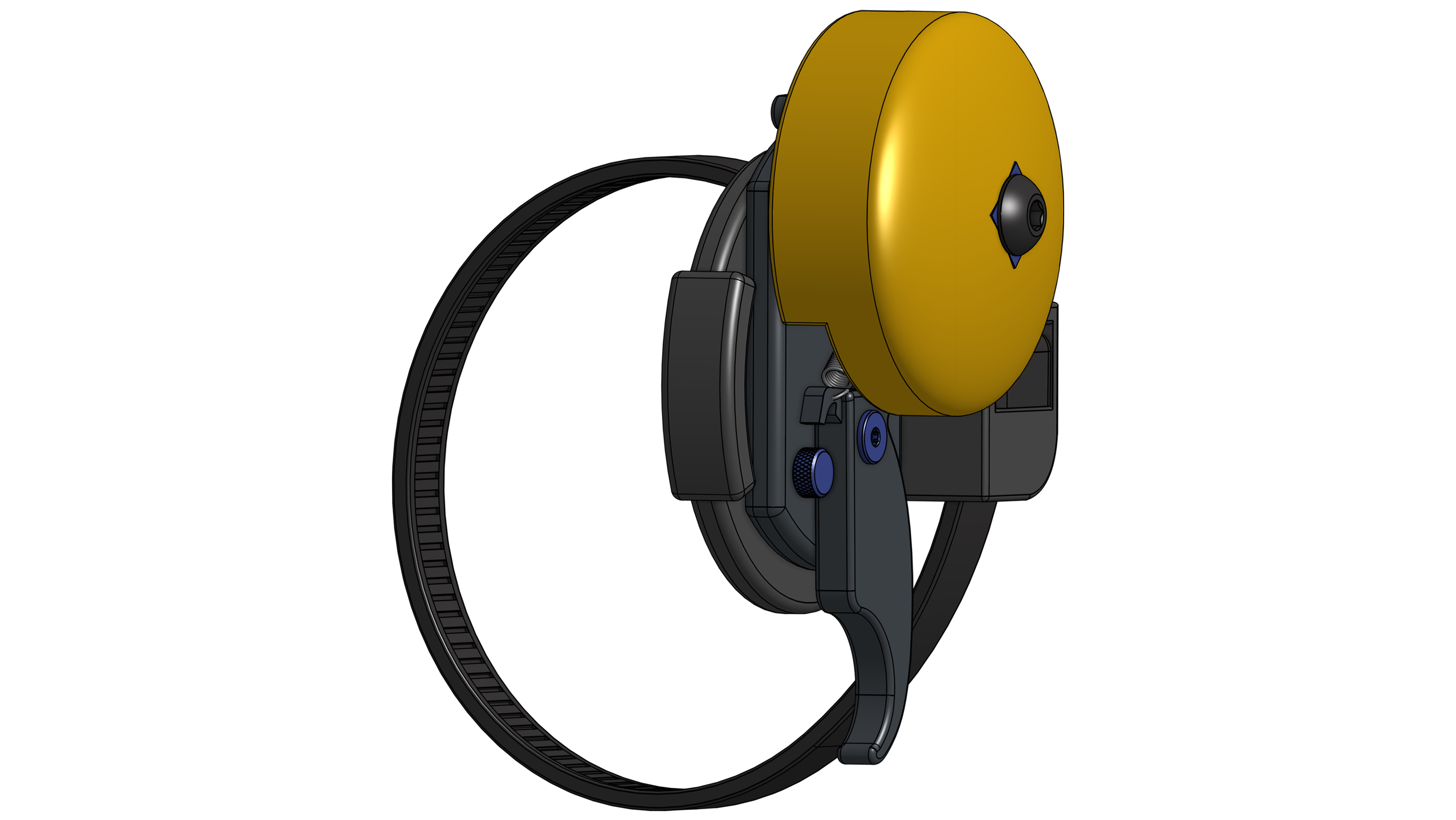

I. Top & Bottom Tool Wheels

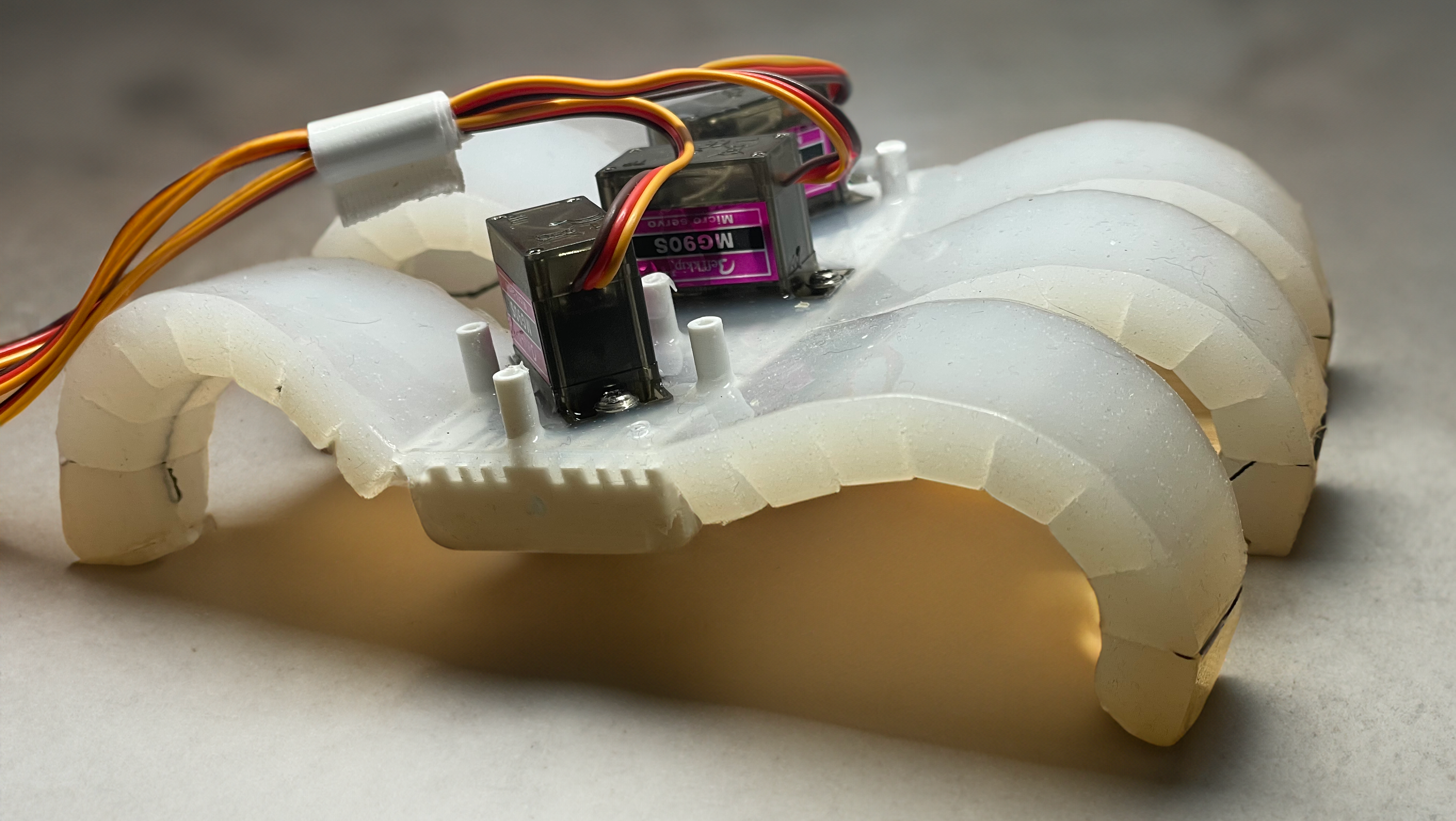

TTW performing fret wire pressing

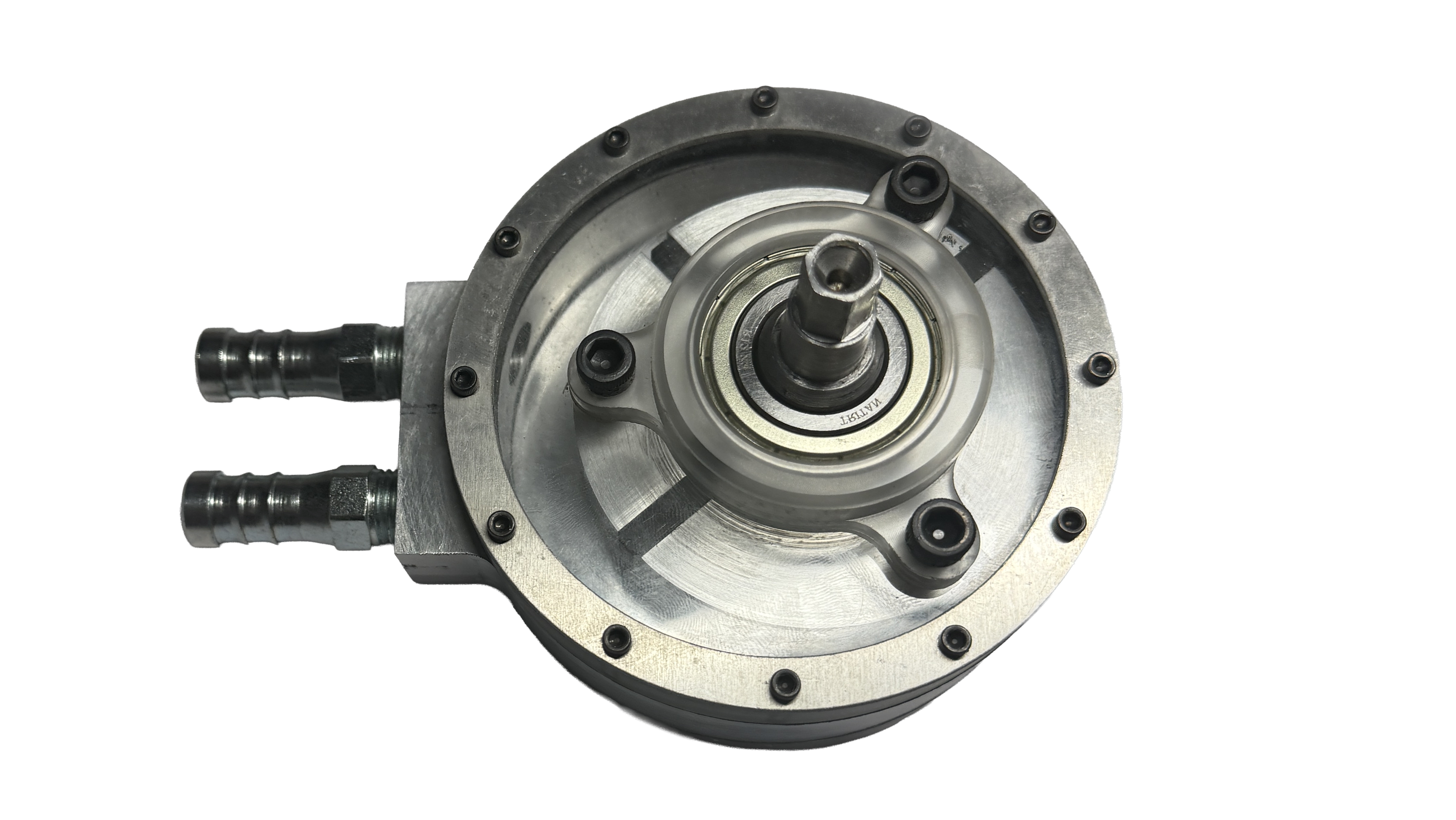

Top & Bottom Tool Wheels

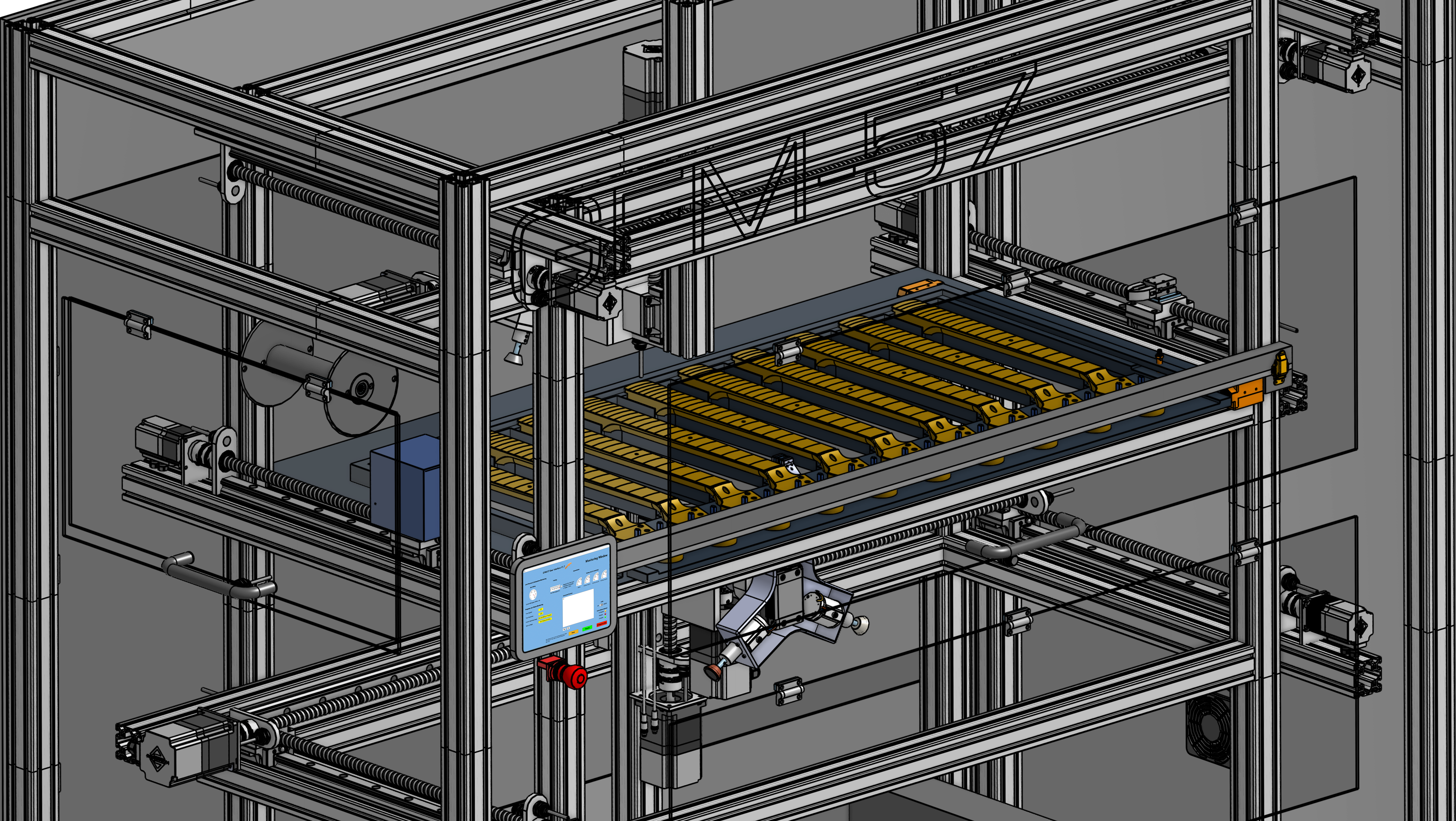

Our design utilizes two rotary tool wheels, the upper tool wheel (UTW) and bottom tool wheel (BTW). These multi-purpose end-effectors cycle rapidly between tooling heads, while maintaining an efficient footprint within the build area.

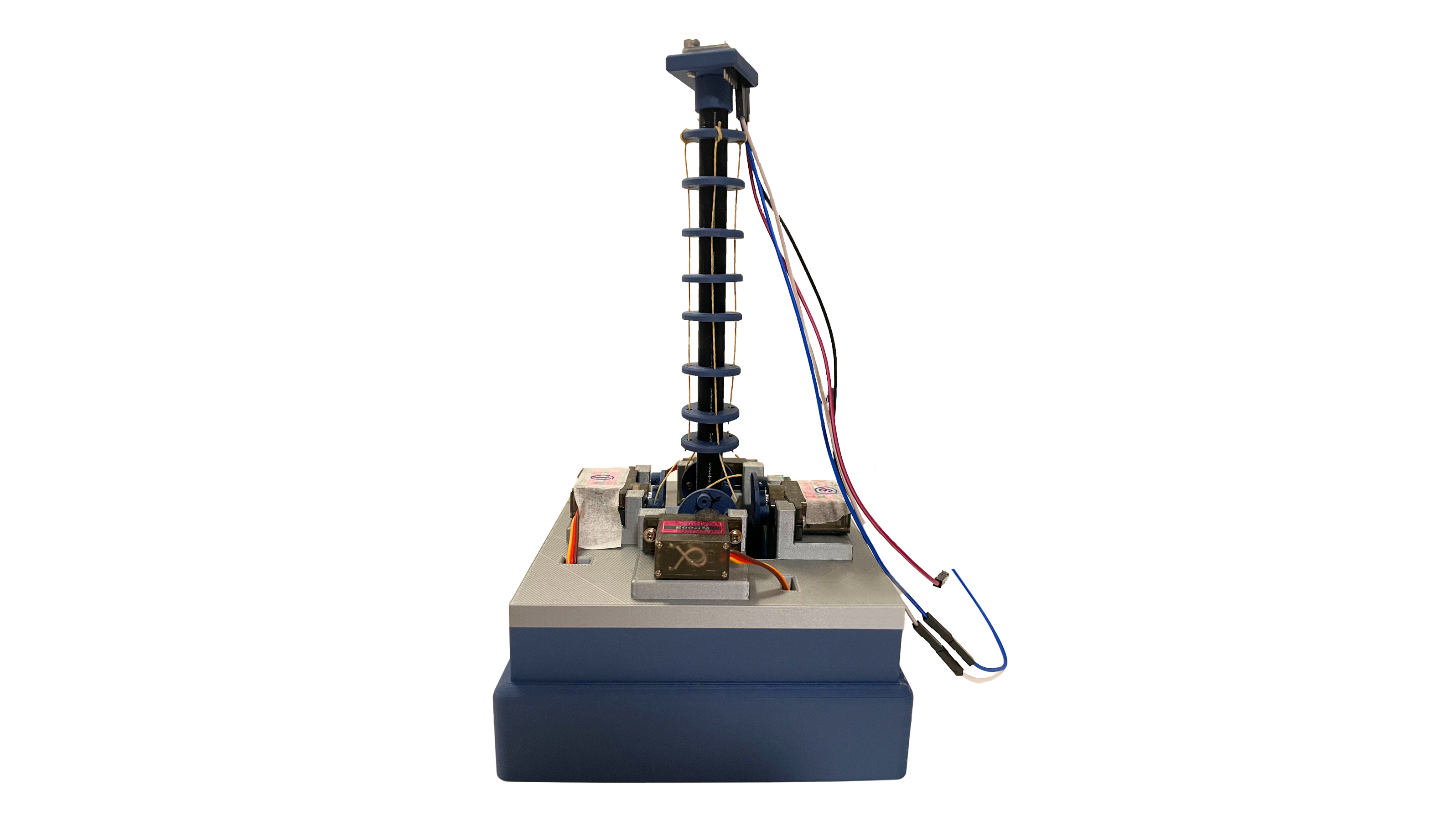

Linear Rail System

This is the first bike bell with an internal striker. All current bike bells impact the exterior of the bell dome. This provides a smaller design footprint and provides a geometric foundation for the design's ergonomic superiority, detailed below.

II. Eater-Feeder System & Neck Rack

III. Linear Rail System & Sensing

IV. Housing

Operation & Features

Fabrication

Numerous fabrication methods were used in the design and prototyping of this project. Custom tooling fixtures were also designed to allow for registration (or "clocking") of the bell dome, so that the necessary alignment for internal striking could be achieved. Other fabrication methods used include, but are not limited to:

• 3D printing (FDM)

• Wire Electrical Discharge Machining (Wire EDM)

• Water Jet Cutting

• CNC

• Lathe

A full report detailing the design and manufacturing processes can be accessed below: